Applications

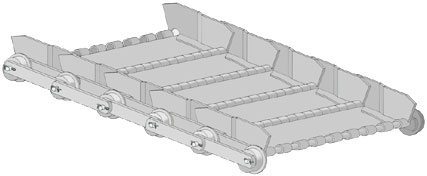

The 6”-9” Steel Hinge Belt is ideal for handling parts, stampings, die castings, screws, scrap, chips, turnings, material wet or dry, horizontal or elevating, single or multiple unit systems. These hinged steel conveyor belts are specially designed for tough industrial environments.

You will find these industrial metal conveyor belts and heavy duty conveyor belts being used in various industries including the following:

Specifications

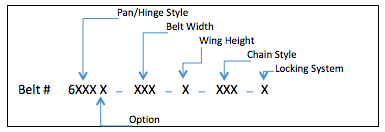

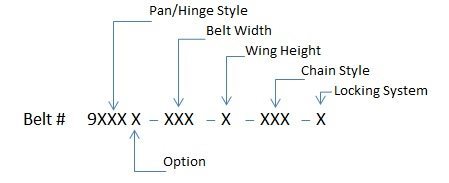

6″ Steel Hinge Belt Configurations

Pan/Hinge

– 229 = 1/4 Thick

– 179 = 3/16 Thick

– P = Optional Perforated

– D = Optional Dimpled

– DP = Optional Dimpled and Perforated

Belt Width – Available in Any Width of 6″ Increments

Wings

– 3 = 3″ High x 1/4 Offset Welded To Pan

– 4 = 4″ High x 1/4 Offset Welded To Pan

Pin – 3/4 Diameter CR1044/1045 End Machined for Locking System. Belt Width Cover Tube.

Modifications – Angle Cleats, Bar Cleats, Impact Shoes/Pads, Top Plates, C-Channel Reinforcements, Trapezoid Reinforcements. Any size, any Spacing.

Pan/Hinge

– 229 = 1/4 Thick

– 179 = 3/16 Thick

– P = Optional Perforated

– D = Optional Dimpled

– DP = Optional Dimpled and Perforated

Belt Width – Available in Any Width of 6″ Increments

Wings

– 3 = 3″ High x 1/4 Offset Welded To Pan

– 4 = 4″ High x 1/4 Offset Welded To Pan

– 6 = 6″ High x 1/4 Offset Welded to Pan

Pin – 3/4 Diameter CR1044/1045 End Machined for Locking System. Belt Width Cover Tube.

Modifications – Angle Cleats, Bar Cleats, Impact Shoes/Pads, Top Plates, C-Channel Reinforcements, Trapezoid Reinforcements. Any size, and Spacing.

Case Studies

May Conveyor, Inc. Rapidly Modifies a Mismatched Belt to Resume Operations

May Conveyor, Inc. Rapidly Modifies a Mismatched Belt to Resume Operations May Conveyor, Inc. Expedites Special Material Procurement to Build a Custom Apron/Beaded Pan Belt

May Conveyor, Inc. Expedites Special Material Procurement to Build a Custom Apron/Beaded Pan Belt May Conveyor, Inc. Delivers a Custom 1000′ Steel Belt in Record Time for Holiday Installation

May Conveyor, Inc. Delivers a Custom 1000′ Steel Belt in Record Time for Holiday Installation

Industry News & Blog

The Different Types of Conveyor Systems Explained

The Different Types of Conveyor Systems Explained How Conveyor Systems Improve Productivity and Quality Control

How Conveyor Systems Improve Productivity and Quality Control 10 Benefits of Conveyor Systems for Modern Warehousing

10 Benefits of Conveyor Systems for Modern Warehousing

Industries Served

- Waste & Recycling

- Machining

- Stamping, Manufacturing

- OEM

- Foundry & Mining

- Automotive

- Food & Tobacco