Applications

The 1.25”- 1.50″ – 2.50″ metal chip conveyor belt is designed for reliable and efficient handling of parts, stampings, die castings, screws, scrap, chips, and turnings. Whether the material is wet or dry, the conveyor performs effectively in horizontal or elevating setups, and supports both single and multiple unit systems. Ideal as a chip conveyor for CNC machines, it helps streamline operations by managing chip removal and material flow with ease.

You will find this belting being used in the following industries:

Features

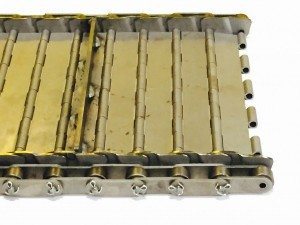

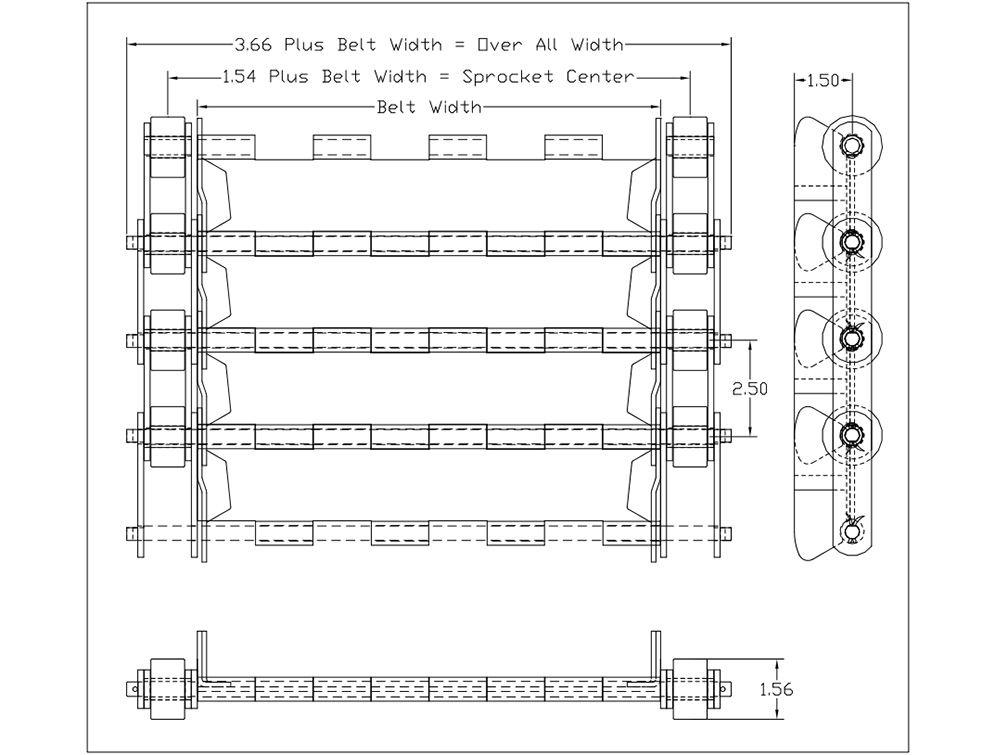

Our hinged steel belt conveyor belting is available in 1-1/4″, 1-1/2″, and 2-1/2″ pitch sizes. Designed with offset interlocking side wings that are securely welded, these belts offer exceptional durability and reliable performance. They are fully interchangeable with most major manufacturers, making them a versatile solution for a wide range of machining and metalworking applications. We also offer beaded apron belts for operations requiring added flexibility and strength. Improving CNC workflow with the right conveyor system starts with dependable belting solutions like these, streamlining chip removal and boosting efficiency.

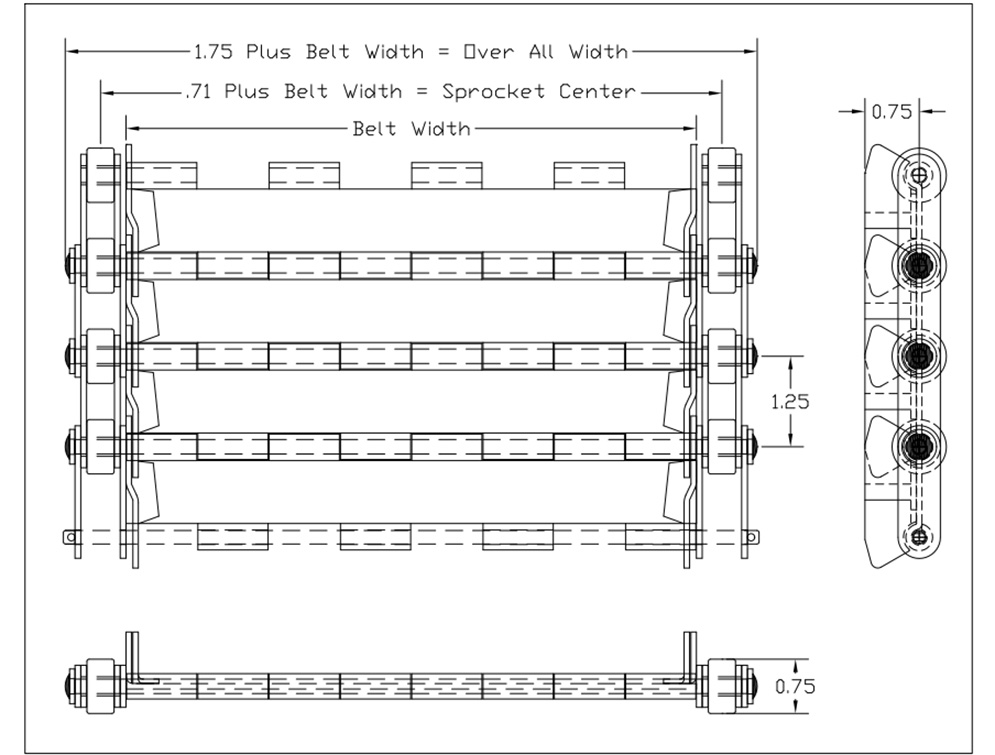

Specifications

Pan/Hinge

– Material 14 GA. (.075)

– Available in Any Width

– P = Optional Perforated

– D = Optional Dimpled

– PD = Optional Perforated and Dimpled

Wings

– .75= 3/4 High 14 Ga. Offset Welded To Pan

– .8R= Optional 13/16 High 11 Ga. Offset Radial

Chain

– Hardened Roller: Flat Face 3/4 Dia. x 3/8 Wide

– Split Roller Bushing

– Links: 3/32 Thick x 9/16 High

Pin

– 3/16 Dia. CR1044/1045

– Locking System – Welded Washer

– Belt Splice 3/32 Cotter Pin

Belt Pull – 650 Lbs.

Modifications

– Optional Bar Cleats, Any Size, Any Spacing.

– Optional Cover Plates, 3/16 Thick x 1″ Wide, Any Spacing

Pan/Hinge

– Material 14 GA. (.075)

– Available in Any Width

– P = Optional Perforated

– D = Optional Dimpled

– PD = Optional Perforated and Dimpled

Wings

– 1R= 1.00 High 11 Ga. Offset Radial

– .75R= Optional 3/4 High 11 Ga. Offset Radial

Chain

– Hardened Roller: Flat Face 7/8 Dia. x 1/2 Wide

– Split Roller Bushing

– Links: 1/8 Thick x 11/16 High

Pan/Hinge

– Material 1/8

– Available in Any Width of 3″ Increments

– D = Optional Dimpled

– PD = Optional Perforated and Dimpled

Wings

– 1/8 Thick x 1-1/2 High – Offset Welded To Pan

Chain

– Roller: Hardened – Flat Face 1-9/16 Dia. x 1″ Wide

– Hardened Split Roller Bushing

– Links: 5/32 Thick x 1″ High

Pin

– 3/8 Dia. CR1044/1045

– Locking System – 1/8 Cotter Pin

Belt Pull – 2,500 Lbs.

Modifications

– Optional Bar Cleats, Any Size, Any Spacing.

– Optional Cover Plates, 3/8 Thick x 1-3/4″ Wide, Any Spacing

Industry News & Blog

Choosing the Right Scrap Conveyor for Metal Stamping – As detailed by MC3 Manufacturing in their article, “Conveyor Considerations for Metal Stamping Scrap Removal,” selecting a conveyor system for metal stamping scrap requires a specialized approach due to the harsh, high-impact environment. Unlike standard conveying applications, stamping scrap removal must handle heavy, sharp materials without compromising durability or system integrity. In the metal stamping… Read More →

Choosing the Right Scrap Conveyor for Metal Stamping – As detailed by MC3 Manufacturing in their article, “Conveyor Considerations for Metal Stamping Scrap Removal,” selecting a conveyor system for metal stamping scrap requires a specialized approach due to the harsh, high-impact environment. Unlike standard conveying applications, stamping scrap removal must handle heavy, sharp materials without compromising durability or system integrity. In the metal stamping… Read More → The Different Types of Conveyor Systems Explained – As outlined by The Engineering Choice in the article “What Is Conveyor System? – Working, And Types”, conveyor systems are essential mechanical tools designed to efficiently transport materials within a defined area. These systems, which can use belts, rollers, chains, or wheels, are key to optimizing both industrial operations and consumer experiences. Used extensively in… Read More →

The Different Types of Conveyor Systems Explained – As outlined by The Engineering Choice in the article “What Is Conveyor System? – Working, And Types”, conveyor systems are essential mechanical tools designed to efficiently transport materials within a defined area. These systems, which can use belts, rollers, chains, or wheels, are key to optimizing both industrial operations and consumer experiences. Used extensively in… Read More → How Conveyor Systems Improve Productivity and Quality Control – As highlighted by BusinessLoad in the article “Seven Essential Benefits of Material Handling and Conveyor Solutions”, integrating conveyor systems with material handling automation brings measurable improvements to every stage of the production cycle—from receiving and processing to storage, picking, and shipping. A well-engineered, connected material handling system offers seven core benefits: faster delivery times, improved… Read More →

How Conveyor Systems Improve Productivity and Quality Control – As highlighted by BusinessLoad in the article “Seven Essential Benefits of Material Handling and Conveyor Solutions”, integrating conveyor systems with material handling automation brings measurable improvements to every stage of the production cycle—from receiving and processing to storage, picking, and shipping. A well-engineered, connected material handling system offers seven core benefits: faster delivery times, improved… Read More → 10 Benefits of Conveyor Systems for Modern Warehousing – As discussed by Lafayette Engineering in the article “10 Reasons Why Warehouse Conveyors Are Essential for Efficient Operations”, conveyor systems have become the backbone of modern warehousing and logistics. These systems dramatically enhance how goods are moved, sorted, and tracked—bringing automation, safety, and precision to fast-paced distribution environments. Warehouse conveyors automate the movement of goods,… Read More →

10 Benefits of Conveyor Systems for Modern Warehousing – As discussed by Lafayette Engineering in the article “10 Reasons Why Warehouse Conveyors Are Essential for Efficient Operations”, conveyor systems have become the backbone of modern warehousing and logistics. These systems dramatically enhance how goods are moved, sorted, and tracked—bringing automation, safety, and precision to fast-paced distribution environments. Warehouse conveyors automate the movement of goods,… Read More →