In heavy-duty industries like mining and foundries, the durability and efficiency of conveyor systems are critical to maintaining productivity. At May Conveyor, we specialize in high-quality conveyor solutions, and our Beaded Apron Conveyor Belts are engineered to withstand abrasive materials, extreme temperatures, and heavy loads—ensuring reliable performance in the most demanding applications.

The Toughest Environments Demand the Strongest Belts

Both mining and foundry operations involve handling materials that can easily wear down standard conveyor belts. Whether it’s transporting mined ore or moving molten metal castings, these processes require belts that offer:

High-impact resistance

Heat tolerance

Minimal material spillage

Long-lasting durability

Our Beaded Apron Conveyor Belts are specifically engineered to meet these challenges head-on.

How Beaded Apron Conveyor Belts Benefit the Mining Industry

Mining operations deal with rocks, minerals, and raw materials that are often jagged, oversized, and highly abrasive. Conventional belts struggle with such loads, leading to excessive wear and frequent downtime.

Our Beaded Apron Conveyor Belts provide:

- Heavy-duty construction to support high tonnage loads

- Thick steel pans that resist punctures and abrasions

- Reinforced chain attachments for secure and smooth movement

- Leak-proof interlocking wings to minimize material loss

These features ensure uninterrupted performance in mining facilities, reducing downtime and improving overall productivity.

The Role of Beaded Apron Conveyor Belts in Foundries

Foundries face unique challenges, such as handling molten metals, casting sand, and industrial slag. Traditional rubber conveyor belts deteriorate quickly under such conditions, making Beaded Apron Conveyor Belts the best choice for foundry applications.

Key benefits include:

- High heat resistance – Capable of withstanding extreme temperatures

- Spillage control – Prevents sand, metal shavings, and other materials from escaping

- Customizable cleats and attachments – Ensures seamless integration with foundry processes

By reducing maintenance and extending belt lifespan, our Beaded Apron Conveyor Belts increase efficiency and lower operating costs for foundries.

Customization Options for Maximum Efficiency

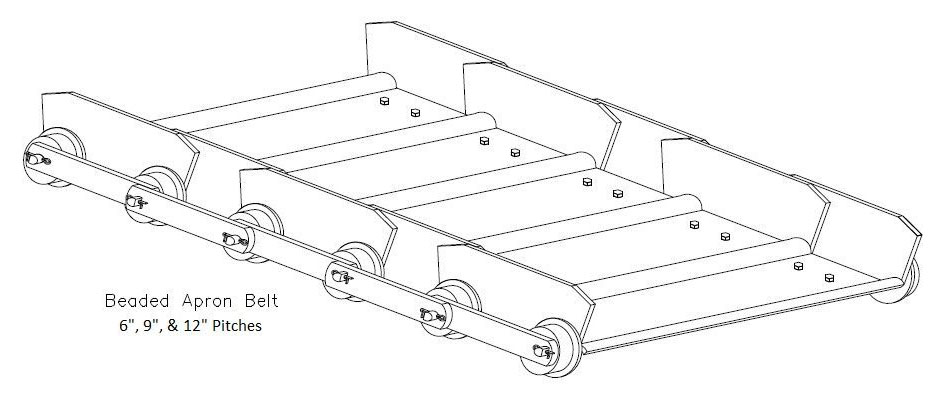

Every mining and foundry operation has unique requirements, which is why we offer fully customizable solutions. Our belts come in:

- Various pitches (6″, 9″, 12″) to suit different applications

- Widths ranging from 12″ to 120″

- Thickness options from 3/16″ to 1/2″

- Heavy-duty chain bars and pin locking systems for added strength

May Conveyor: A Trusted Partner in Industrial Solutions

With decades of experience in manufacturing high-quality conveyor belts, May Conveyor is committed to delivering durable and cost-effective solutions. We understand the demands of the mining and foundry industries and provide Beaded Apron Conveyor Belts that maximize efficiency, safety, and longevity.

If you’re looking for a conveyor belt that can handle your toughest challenges, get in touch with us today. Let’s find the right solution for your business!