In the article ‘Considerations for Selecting Conveyors‘ from Assembly Magazine, the complexity of choosing a conveyor for an automation project is emphasized. This decision is far from a ‘one-size-fits-all’ scenario, given the diverse nature of automation applications and the corresponding conveyor options and features.

Understanding the unique requirements of different industries involves acknowledging varying health and safety regulations and the specific features needed for various automation applications. The article highlights the importance of thoroughly exploring the market’s available options before making a decision tailored to a particular application.

The Basics

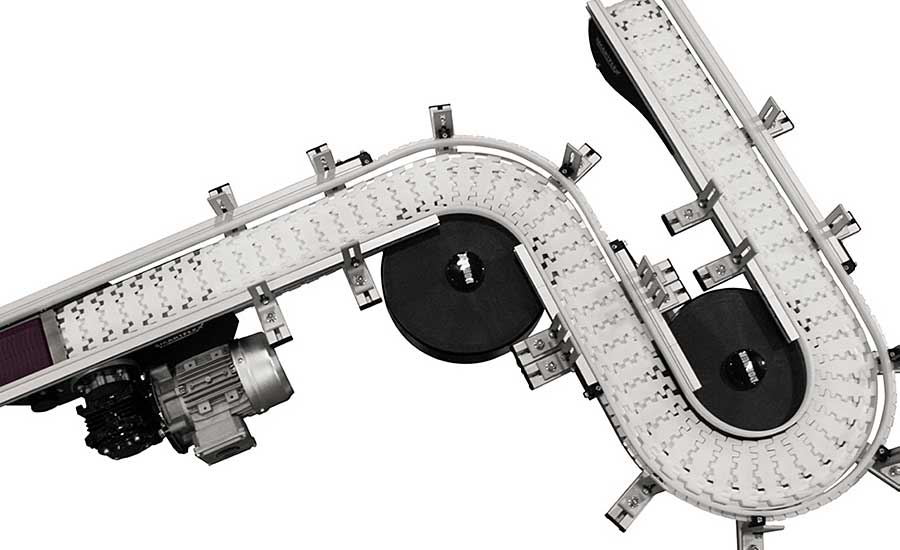

Before delving into industry-specific customization, engineers should address fundamental questions about the conveyor. One crucial consideration is determining which part of the automation line the conveyor serves, directly impacting the suitable model for the application. Factors such as the location of the drive become significant; for instance, some conveyors have the drive on one end, while others have a more centered drive. This distinction matters because a centered drive allows flexibility at the ends, facilitating the transfer of items from one end to the other without obstruction. Various mounting options, such as bottom, top, or side mounts, add to the customization possibilities.

Another critical factor is whether products will accumulate on the conveyor, influencing the choice of belt style. Evaluating whether a flat belt or a cleated one would be more suitable depends on the type of product being transferred and the required friction.

To learn more about May Conveyor products click here

Photo and article with all rights reserved, courtesy of assemblymag.com