Conducting an in-depth exploration into the world of roller conveyors, this section sheds light on the mechanics, uses, and construction of these integral components of material handling systems. The information is sourced from the article “Roller Conveyors” on IQS Directory.

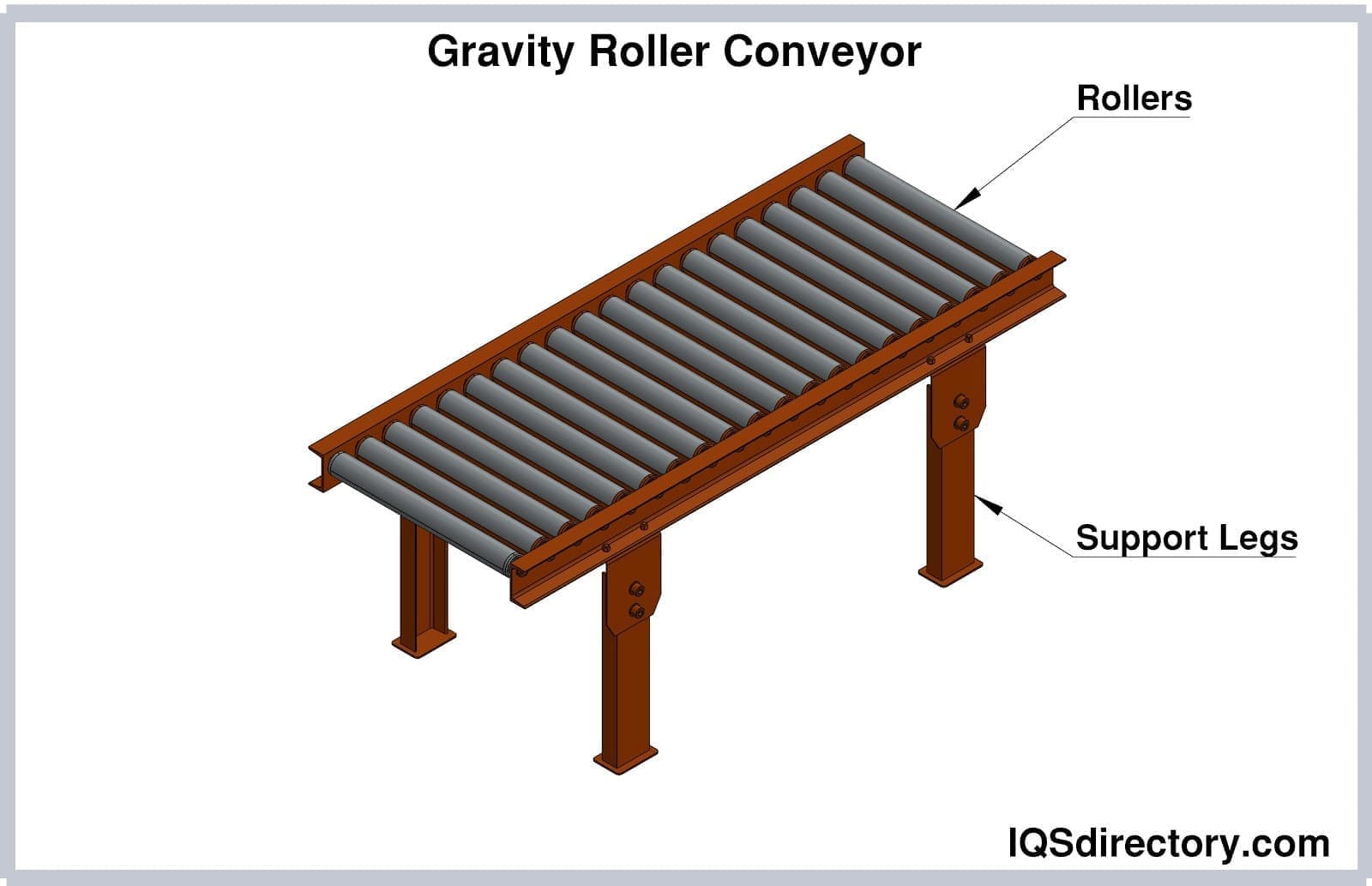

Roller conveyors play a crucial role in material handling systems, utilizing evenly spaced cylindrical rollers to transport various items across open spaces or between different levels. Positioned at a convenient height for manual access and loading, the frame of roller conveyors facilitates the smooth movement of materials with rigid, flat surfaces. Uses for roller conveyors encompass accumulation applications, product inertia reduction, and high-speed sorting. Drive roller conveyors, featuring rollers connected to a motor by a chain, shaft, or belt, ensure uniform material velocity, offer reversibility, and enable vertical movement from lower to higher levels.

While roller conveyors exhibit variations in structure and features, they share fundamental characteristics. Powered roller conveyors utilize small belts and plastic spools for traction, with friction belts or chains beneath the conveyor powering heavy-duty rollers. These are connected to a shaft linked to an electric motor, driving the rollers efficiently.

Click here to delve deeper into May Conveyor’s expertise in conveyor systems.

Photo and article with all rights reserved, courtesy of iqsdirectory.com