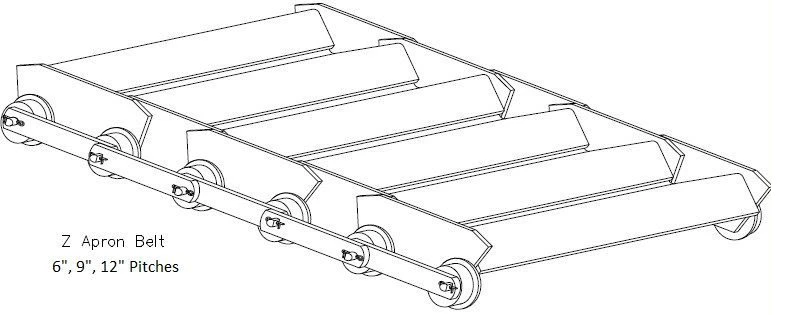

In mining and foundry operations, efficiency is everything. These industries require conveyor belts that can handle extreme conditions, from abrasive ores in mines to molten metal in foundries. At May Conveyor, we design our “Z” Apron Pan Conveyor Belts to improve efficiency, durability, and safety, ensuring uninterrupted material handling in the toughest environments.

Challenges in Mining and Foundries

Mining Industry Challenges

- Heavy and abrasive materials (coal, ores, aggregates) can quickly wear out standard belts

- Material spillage leads to product loss and safety hazards

- High-impact loads can cause belt failure or frequent maintenance downtime

Foundry Industry Challenges

- Extreme temperatures cause belt degradation and failure

- High impact from castings and slag requires reinforced belt construction

- Dust and debris accumulation can lead to operational inefficiencies

How “Z” Apron Pan Conveyor Belts Improve Efficiency

1. Heavy-Duty Durability for Harsh Conditions

Mining and foundry materials require belts that won’t buckle under pressure. Our “Z” Apron Pan Conveyor Belts are designed to handle extreme loads and conditions, featuring:

- High-strength steel pans that resist wear and impact

- Reinforced chains for superior load-bearing capacity

- Extra heavy-duty chain bars for extreme weight applications

This ensures long-term reliability, reducing unexpected breakdowns and costly downtime.

2. Improved Spill Prevention & Material Retention

Spillage is a significant concern, particularly in high-volume operations. Our “Z” Apron Pan Conveyor Belts feature:

- Leak-proof interlocking wings to prevent material loss

- Extended inner chain bars for increased belt stability

- Custom cleats and impact pads for enhanced material control

These features maximize material handling efficiency, ensuring that every ounce of material reaches its destination without unnecessary waste.

3. Customization to Fit Any Industrial Need

No two operations are the same, which is why we offer customization options for our “Z” Apron Pan Conveyor Belts , including:

- Custom widths (12″ to 120″) for various conveyor setups

- Different locking mechanisms to suit operational preferences

- Additional heat-resistant modifications for foundry applications

This allows businesses to optimize their conveyor systems for peak efficiency and longevity.

Industries That Benefit from “Z” Apron Pan Conveyor Belts.

- Mining – Reliable transport of raw materials and ore

- Steel & Metal Foundries – Efficient handling of hot and abrasive materials

Why Choose May Conveyor?

At May Conveyor, we manufacture durable, high-performance conveyor belts tailored to meet the toughest industry demands. Our engineering expertise and commitment to quality make us a trusted provider for mining and foundry professionals.

If you’re looking for a high-strength, long-lasting conveyor solution, explore our “Z” Apron Pan Conveyor Belts today. Contact us to find the right belt for your business!