Case Studies

May Conveyor, Inc. Rapidly Modifies a Mismatched Belt to Resume Operations

May Conveyor, Inc. Rapidly Modifies a Mismatched Belt to Resume Operations May Conveyor, Inc. Expedites Special Material Procurement to Build a Custom Apron/Beaded Pan Belt

May Conveyor, Inc. Expedites Special Material Procurement to Build a Custom Apron/Beaded Pan Belt

Belt Types

Chip Conveyor Belts

Combination Belts

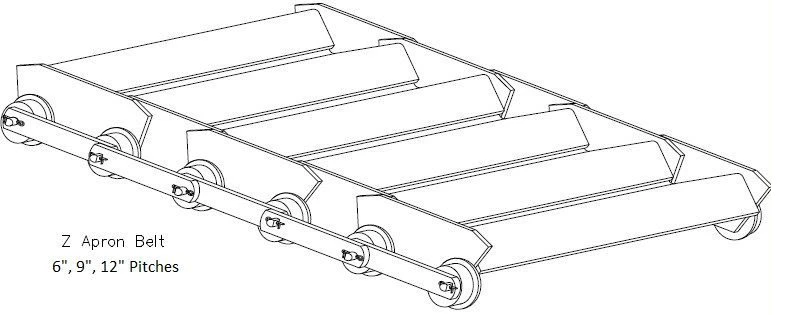

“Z” Apron Pan Belts

Steel Hinge Belts

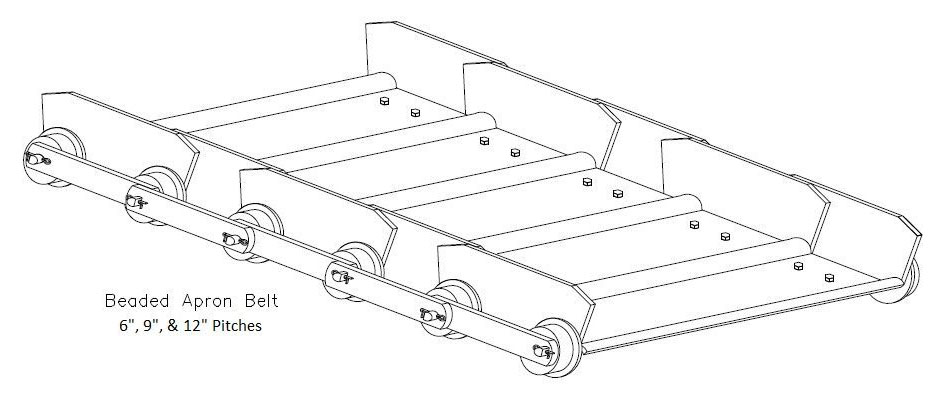

Beaded Apron Belts

Specialty Engineered Belting

Parts

Steel Hinge Conveyor Belts 6″ & 9″ Pitch Belt Specifications

6″ & 9″ Pitch Chain Parts Layout

Part Number and Descriptions

Request a Quote

Interested in our Belts, Chains or Parts? Request a quote today.

Boost Productivity with Precision Chip Conveyor Solutions

At May Conveyor, we understand that efficiency is the backbone of any successful manufacturing or metalworking operation. One of the biggest challenges in these industries is managing metal chips, shavings, and debris that accumulate during production. Without an effective solution, these byproducts can cause machine downtime, create safety hazards, and reduce overall productivity. That’s why…

Why Custom Conveyor Systems Improve Plant Efficiency

As highlighted in LinkedIn by Koos in the article “Advantages Of Implementing A Custom Conveyor System In Your Production Plant,” conveyor systems are essential tools in warehouses, factories, and processing facilities worldwide. While off-the-shelf conveyors can perform basic functions, custom conveyor systems offer tailored advantages that increase operational efficiency and reduce long-term costs. Custom conveyors…

Why Beaded Apron Conveyor Belts Are Ideal for Mining & Foundries

In heavy-duty industries like mining and foundries, the durability and efficiency of conveyor systems are critical to maintaining productivity. At May Conveyor, we specialize in high-quality conveyor solutions, and our Beaded Apron Conveyor Belts are engineered to withstand abrasive materials, extreme temperatures, and heavy loads—ensuring reliable performance in the most demanding applications. The Toughest Environments…

How Metal Fabrication Powers Efficient Material Handling Solutions

As highlighted by Simon Jones on LinkedIn in his article, “Metal Fabrication and Conveyor Systems,” metal fabrication is a specialized process that involves cutting, shaping, and molding raw metal materials into finished products. This intricate process requires a combination of expert craftsmanship and advanced machinery to ensure precision and quality. While modern technology and computer-aided…

Boost Productivity with Precision Chip Conveyor Solutions

In manufacturing and metalworking industries, the efficiency of material handling can significantly impact productivity. At May Conveyor, we specialize in high-quality conveyor solutions, and our Chip Conveyor Belts are designed to optimize the removal of metal chips, shavings, and debris, ensuring a clean and efficient workspace. The Importance of Chip Conveyor Belts in Manufacturing Metal…

The Future of Sheet Metal Bending: Kit-Based Production Made Easy

As reported by The Fabricator in their article, “Precision Sheet Metal Folding Technology Enables Kit Manufacturing,” manufacturers have always pursued more efficient ways to improve production. Advancements in machinery and tools have continuously driven better margins, opened new markets, and addressed labor challenges. One critical area of improvement is the relationship between blanking and bending.…

How “Z” Apron Pan Conveyor Belts Boost Efficiency in Mining & Foundries

In mining and foundry operations, efficiency is everything. These industries require conveyor belts that can handle extreme conditions, from abrasive ores in mines to molten metal in foundries. At May Conveyor, we design our “Z” Apron Pan Conveyor Belts to improve efficiency, durability, and safety, ensuring uninterrupted material handling in the toughest environments. Challenges in…

Fast Study Explores Conveyor-Belt Solar Hydrogen Reactors

As reported by FuelCellsWorks in their article “Hot Solar Hydrogen Reactors on a Conveyor Belt Get a Fast Study”, MIT researchers have developed an innovative train of solar reactors using a conveyor belt system to significantly enhance the efficiency of solar thermochemical hydrogen (STCH) production. This system recycles 70% of waste heat, dramatically improving heat-to-hydrogen…

Beaded Apron Conveyor Belts: Durable, Reliable & Heavy-Duty Solutions

At May Conveyor, we understand the critical role that conveyor belts play in heavy-duty industrial operations. When it comes to handling large, abrasive, and high-impact materials, having the right belt is essential for efficiency, safety, and longevity. That’s why we manufacture and supply Beaded Apron Conveyor Belts—designed to withstand extreme conditions while providing exceptional performance.…

What Is a Conveyor System? Types, Uses, and Benefits Explained

As outlined by Industrial.ph in their article “What is a Conveyor System?”, conveyor systems are essential for efficiently transporting goods and materials in industries such as manufacturing, agriculture, food processing, and construction. These systems enhance productivity by ensuring smooth and consistent movement of materials, reducing manual labor, and optimizing workflow. Depending on the application, different…

Boost Metal Stamping with Precision Chip Conveyor Solutions

In the metal stamping industry, precision and efficiency are critical to meeting production goals and maintaining product quality. At May Conveyor, we understand that a reliable, purpose-built chip conveyor system is essential for ensuring smooth operations. Our conveyor solutions, especially designed for chip and material handling, enable your team to focus on producing consistent, high-quality…

How Micro Factories Are Changing Car Production

As detailed by Assembly Magazine in their article “Conveyor-Less Micro Factories for Urban Car Production,” the automotive industry is shifting from mass customization to mass individualization, driven by consumer demand for highly personalized vehicles. This trend, accelerated by the rise of autonomous electric vehicles (AEVs), necessitates a new approach to car manufacturing—one that emphasizes flexibility…