Case Studies

May Conveyor, Inc. Rapidly Modifies a Mismatched Belt to Resume Operations

May Conveyor, Inc. Rapidly Modifies a Mismatched Belt to Resume Operations May Conveyor, Inc. Expedites Special Material Procurement to Build a Custom Apron/Beaded Pan Belt

May Conveyor, Inc. Expedites Special Material Procurement to Build a Custom Apron/Beaded Pan Belt

Belt Types

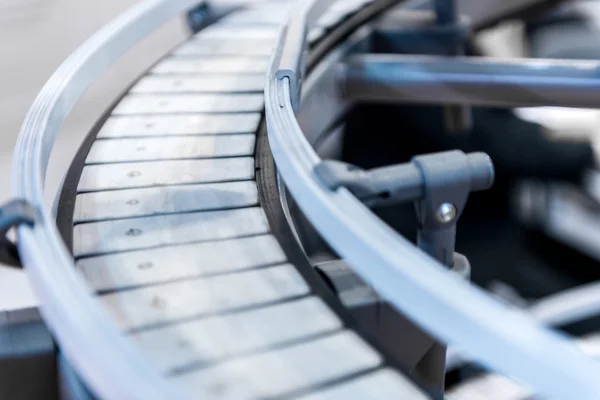

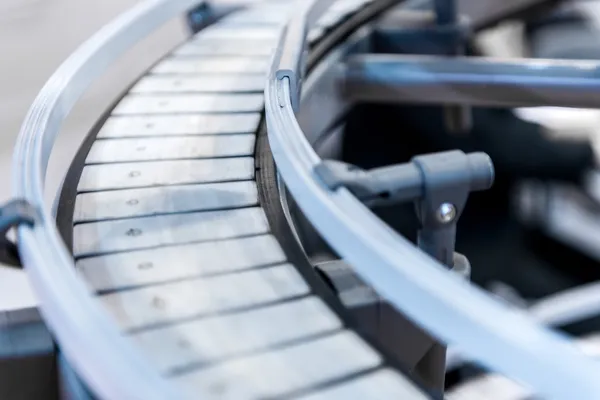

Chip Conveyor Belts

Combination Belts

“Z” Apron Pan Belts

Steel Hinge Belts

Beaded Apron Belts

Specialty Engineered Belting

Parts

Steel Hinge Conveyor Belts 6″ & 9″ Pitch Belt Specifications

6″ & 9″ Pitch Chain Parts Layout

Part Number and Descriptions

Request a Quote

Interested in our Belts, Chains or Parts? Request a quote today.

How Conveyor Belt End-of-Life Choices Impact Sustainability

As published by ScienceDirect in “Toward the Sustainable Use of Conveyor Belts: Life Cycle Assessment of End-of-Life Options,” researchers examined how different end-of-life strategies affect the environmental impact of conveyor belts. The study evaluates options such as recycling, reuse, and disposal through a life cycle assessment framework. Findings show that selecting more sustainable end-of-life pathways…

Choosing the Right Conveyor System

As presented on ResearchGate in “Study of Different Types of Conveyor System and Their Use According to the Various Needs of Different Industries,” conveyor systems are designed to move materials efficiently across manufacturing, warehousing, mining, and processing environments. Common systems include belt conveyors, roller conveyors, chain conveyors, screw conveyors, and pneumatic conveyors, each suited to…

Seeing Opportunity Through the Conveyor Belt

As described by Andy Taylor in “The Sushi Restaurant Conveyor Belt of Opportunity,” conveyor belts symbolize continuous flow and accessible opportunity. In sushi restaurants, items move predictably past customers, allowing them to engage when the timing feels right. This steady movement creates visibility, choice, and efficiency, turning motion into an interactive experience rather than a…

Breaking Free from the Conveyor Belt Mindset

As written on Medium in “Get Off the Conveyor Belt,” the conveyor belt is used as a metaphor for systems that move people forward without pause or reflection. Staying on the belt often means following predefined paths, routines, or expectations without questioning whether they still serve a meaningful purpose. Stepping off allows individuals and organizations…

Knowing When to Step Off the Conveyor Belt

As written by Maryanne Pope in “Pushing the STOP Button: The Importance of Getting Off the Conveyor Belt,” the conveyor belt serves as a metaphor for systems that keep moving without reflection or intention. When people remain on autopilot, they risk losing sight of purpose, creativity, and long-term outcomes. Stepping off the conveyor belt allows…

The Rise of the Conveyor Belt Era in Modern Industry

As discussed on Medium in the article “Welcome to the Conveyor Belt Era,” conveyor systems symbolize the modern age of automation and efficiency. Once a simple tool for transporting goods, the conveyor belt has become a cornerstone of industrial production, enabling faster assembly, reduced costs, and streamlined logistics. The technology represents a broader shift toward…

Precision Indexing Conveyors in Automotive Manufacturing

As detailed by Assembly Magazine in the article “How to Implement a Precision Indexing Conveyor in Automotive Manufacturing,” precision indexing conveyors play a key role in improving workflow accuracy and consistency. These systems allow components to move through production in controlled, repeatable steps, enabling precise placement, assembly, and inspection. This level of accuracy is crucial…

The Role of Conveyor Systems in the Automotive Industry

As explained by FasterCapital in the article “Conveyor Belts and Assembly Line and Automotive Industry,” conveyor systems have been fundamental to automotive manufacturing since the early days of the assembly line. By automating the movement of materials, conveyor belts enable faster production, consistent quality, and reduced manual labor. These systems streamline processes from parts transport…

How Conveyor Optimization Enhances Recycling Efficiency

According to ResearchGate in “Optimization of Recyclable Materials Collection on Conveyor Belts”, the efficiency of waste sorting and recycling heavily depends on how conveyor systems are designed and operated. The study explores strategies to optimize material flow, detection accuracy, and sorting performance, helping recycling facilities increase recovery rates while reducing operational costs. By integrating automation,…

Why Conveyor Maintenance Matters in Material Recovery Facilities

In “The Crucial Role of Clean and Operational Conveyor Belts in Materials Recycling Plants” by Hoverdale, maintaining conveyor systems is essential for efficiency and safety in recycling facilities. Carryback, blockages, and material buildup can significantly reduce throughput and cause unnecessary downtime. Regular cleaning and maintenance prevent system inefficiencies while extending equipment lifespan. Conveyor belt scrapers,…

Applications and Benefits of Belt Conveyors

As described by IQS Directory in “What Are the Applications and Benefits of Belt Conveyors?”, belt conveyors are among the most versatile and efficient material handling systems used across industries. They transport bulk materials and products smoothly and continuously, supporting industries such as mining, food processing, automotive, and packaging. The advantages of belt conveyors include…