Waste & Recycling Solutions

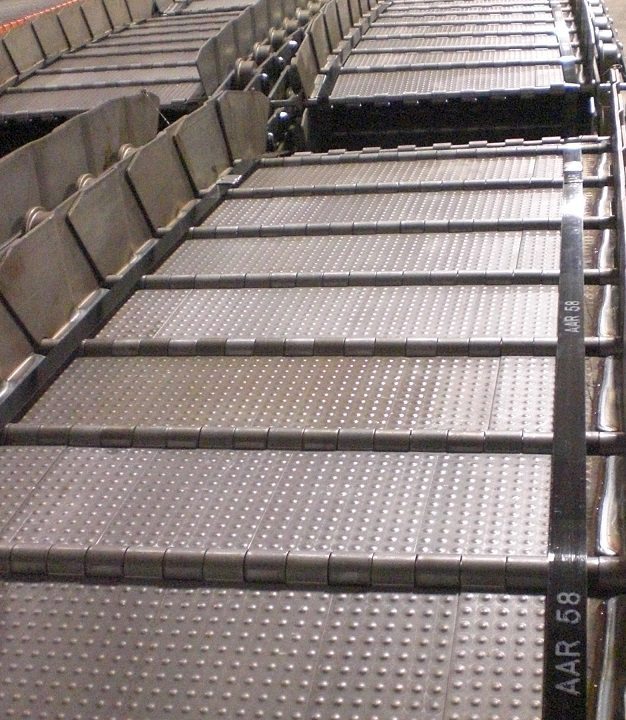

May Conveyor offers rugged, efficient conveying solutions tailored to the Waste & Recycling industry. Their heavy-duty products—Steel Hinge Belts, Combination Belts, Conveyor Chains, and Specialty Belting—are engineered to handle harsh waste streams, including metal scrap, chips, sludge, and abrasive materials. Built for durability and sustainability, they ensure efficient, reliable material handling in both new installations and retrofit applications.

Robust hinged steel belts are designed for the toughest waste-handling environments:

Lightweight yet strong, these belts bridge steel hinge and standard belt technologies:

Precision-engineered conveyor chains form the backbone of scalable systems:

Custom belts designed for extreme environments where standard belts fail:

Why Choose May Conveyor for Waste & Recycling

Durability & Reliability

Hardened steel, journaled chains, and specialty materials built for tough conditions

Retrofit-Friendly

Combination belts are designed to replace steel hinge belts with minimal modifications

Typical Applications in Waste & Recycling

| Product | Typical Use Cases | Core Benefits |

| Steel Hinge Belts | Heavy-metal scrap, chips, incline areas | Durability, custom features, long-life |

| Combination Belts | Retrofit, mixed-waste, lighter loads | Lighter, cost-effective, flexible adaption |

| Conveyor Chains | Core support for heavy belt systems | Strength, smooth operation, low wear |

| Specialty Belting | Chemical, heat, corrosion-rich processes | Tailored resistance and long-term reliability |

May Conveyor delivers robust, reliable, and tailored conveyor solutions for the Waste & Recycling industry. Whether it’s heavy steel belts, retrofit combinations, precision chains, or custom-engineered belts, they offer the strength and adaptability you need—with service to match.