Machining Solutions

May Conveyor delivers precision-engineered heavy-duty material handling conveyor belts and systems tailored for the machining industry. Their robust product line—including industrial chip conveyor belts, conveyor chains for metalworking, and Specialty Engineered Belting—is built specifically to handle the abrasive metal chips, scrap, and harsh operational conditions found in modern machining environments.

These conveyor solutions, featuring industrial chip conveyor belts and durable conveyor belting for metalworking, are ideal for high-volume applications like CNC systems, lathes, and milling environments. They also offer specialized conveyor belts for stamping applications. May Conveyor ensures efficient chip removal, extremely robust construction, and long service life using high-quality conveyor belting for manufacturing.

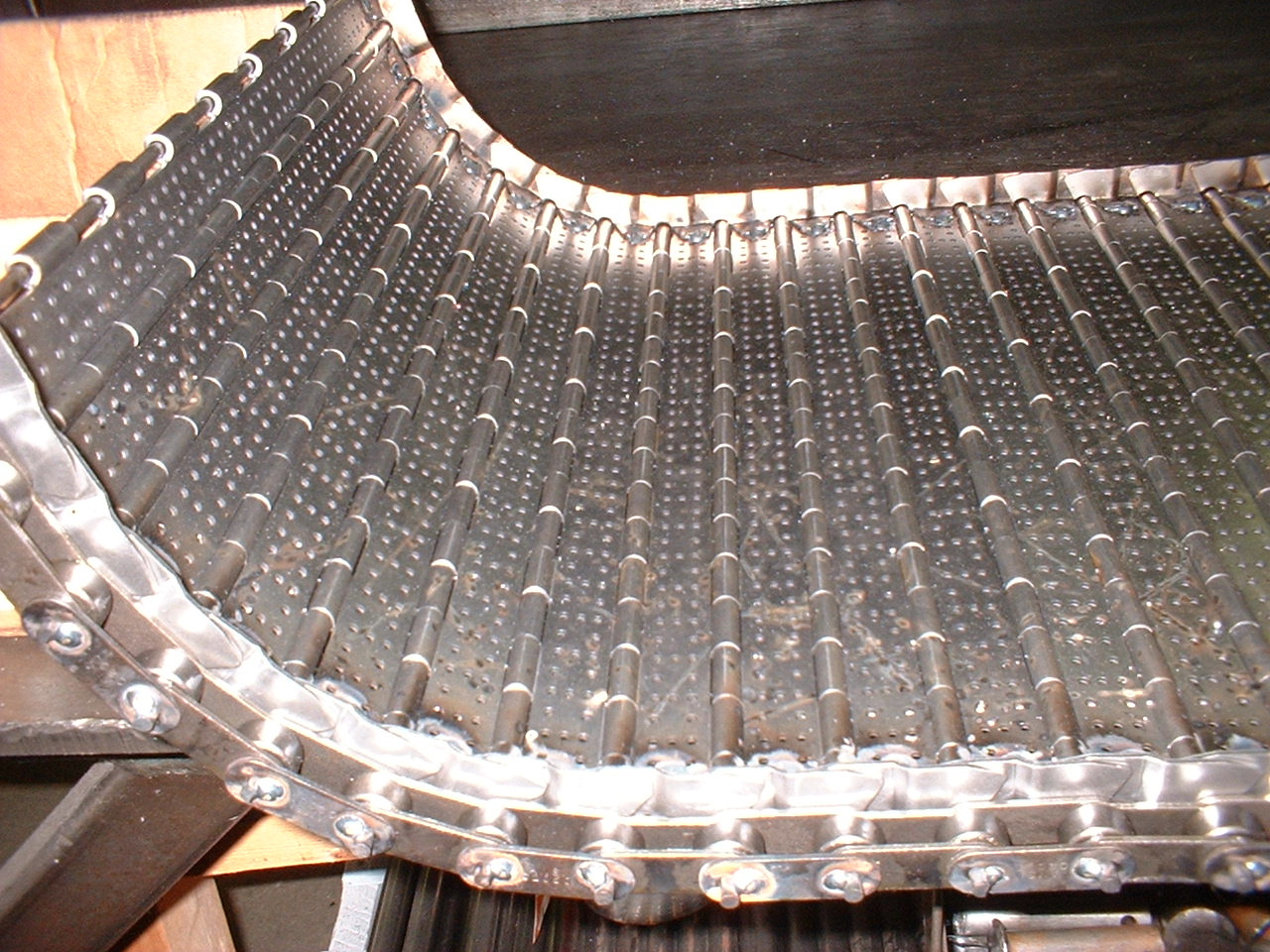

Heavy-duty hinged steel belts optimized for chip and scrap handling in machining systems.

Heavy-duty industrial chains built for strength and longevity in conveyor systems.

Custom belts designed for extreme machining environments with corrosive or high-temperature elements.

Why Choose May Conveyor for Machining

Typical Applications in Machining

| Product | Typical Use Cases | Core Benefits |

| Chip Conveyor Belts | Chips, turnings, castings, CNC scrap | High load capacity, custom options, OEM-fit |

| Conveyor Chains | Heavy-duty chip handling systems | Strength, modularity, smooth long-term use |

| Specialty Belting | Corrosive, chemical, or heat-intensive systems | Tailored resistance, durability, long lifespan |

May Conveyor provides robust, efficient, and customizable conveying systems for the machining industry. Whether your operation needs rugged chip belts, heavy-duty chains, or engineered specialty belts, May Conveyor delivers the performance and reliability your machines demand.