Automotive Industry Solutions

May Conveyor provides high-performance automotive conveyor systems specifically designed for the demanding environments of the Automotive industry. From precision-built conveyor chains for OEMs to robust steel hinge belts and custom-engineered belting, May Conveyor delivers durability, configurability, and operational efficiency to support automotive production, parts handling, and scrap management. These automotive conveyor systems are designed to boost productivity and reduce downtime across operations.

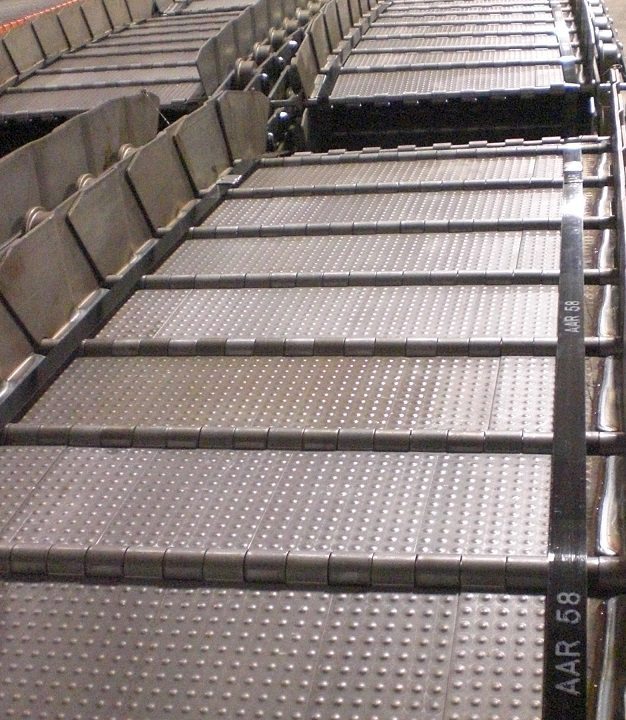

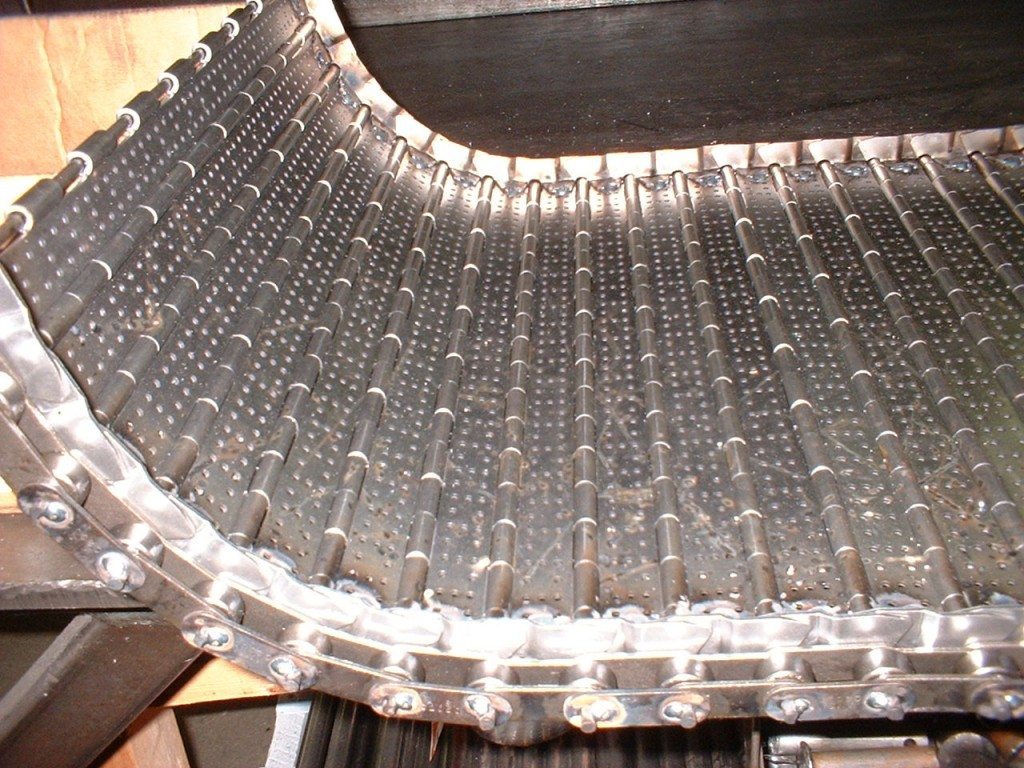

Engineered for rugged automotive conveyor systems in manufacturing and stamping operations, these belts are built to handle hot or oily scrap with ease and resist wear caused by constant contact with heavy metal parts. They are ideal for efficiently transporting press shop waste and bulk materials, and their robust design makes them well-suited for integration with waste handling equipment, ensuring reliable performance in harsh industrial settings.

Built for smooth, load-bearing performance in automotive conveyor systems and production facilities, these conveyor chains for OEMs and Tier 1 suppliers are precision-engineered to meet the high standards of modern manufacturing. They offer custom link designs to accommodate tight tolerance requirements and are available with corrosion-resistant coatings for enhanced durability in harsh environments. While primarily designed for the automotive sector, these chains are also suitable for use as conveyor chains for food industry applications, demonstrating their adaptability across industries.

Tailored for complex automotive conveyor systems, these specialty belts feature modular designs that allow for flexible layouts and easy adaptation to various production needs. Built with high-temperature resistant materials, they are ideal for demanding environments and integrate seamlessly into robotic cells and automated systems. This engineering focus also supports improved conveyor system maintenance and helps maximize overall equipment uptime.

Why Choose May Conveyor for the Automotive Industry

Industry Alignment

Deep experience supporting automotive conveyor systems, manufacturing, and metal processing applications

Typical Applications in Automotive

| Product | Typical Use Cases | Core Benefits |

| Steel Hinge Belts | Metal stamping, scrap handling, incline transfer | Extreme durability, customizable structure |

| Conveyor Chains | Load-bearing conveyor bases | Smooth motion, long lifespan, reduced wear |

| Specialty Belting | Oil-rich, thermal, or unique geometry parts | Custom fit, resistant to chemicals and heat |

May Conveyor delivers proven, precision-engineered automotive conveyor systems that meet the rigorous demands of automotive manufacturing. From production line efficiency to rugged scrap management, their belts and conveyor chains for OEMs help keep automotive plants moving with strength and reliability.