Applications

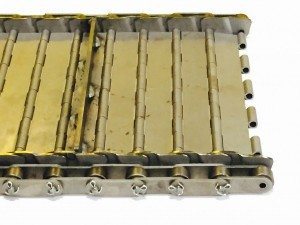

The 1.25”- 1.50″ – 2.50″ Chip Conveyor Belt is ideal for handling parts, stampings, die castings, screws, scrap, chips, turnings, material wet or dry, horizontal or elevating, single or multiple unit systems.

You will find this belting being used in the following industries:

Features

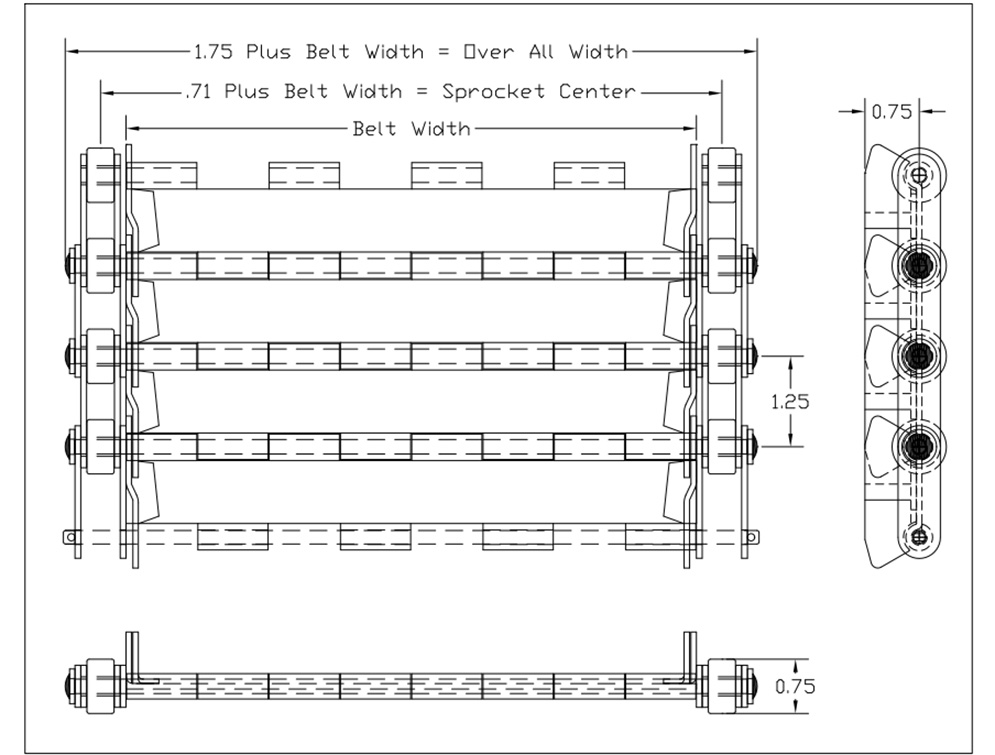

Steel hinged conveyor belting available in 1-1/4″, 1-1/2″, and 2 1/2″ pitch. Offset interlocking side wings are welded. These belts are interchangeable with most major manufacturers

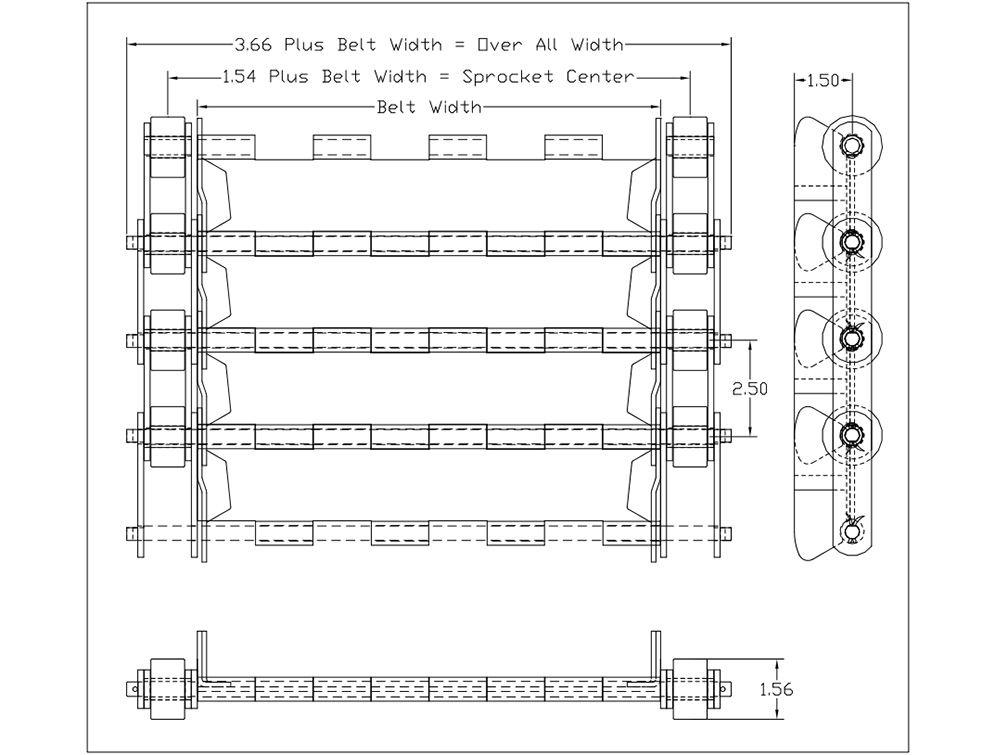

Specifications

Pan/Hinge

– Material 14 GA. (.075)

– Available in Any Width

– P = Optional Perforated

– D = Optional Dimpled

– PD = Optional Perforated and Dimpled

Wings

– .75= 3/4 High 14 Ga. Offset Welded To Pan

– .8R= Optional 13/16 High 11 Ga. Offset Radial

Chain

– Hardened Roller: Flat Face 3/4 Dia. x 3/8 Wide

– Split Roller Bushing

– Links: 3/32 Thick x 9/16 High

Pin

– 3/16 Dia. CR1044/1045

– Locking System – Welded Washer

– Belt Splice 3/32 Cotter Pin

Belt Pull – 650 Lbs.

Modifications

– Optional Bar Cleats, Any Size, Any Spacing.

– Optional Cover Plates, 3/16 Thick x 1″ Wide, Any Spacing

Pan/Hinge

– Material 14 GA. (.075)

– Available in Any Width

– P = Optional Perforated

– D = Optional Dimpled

– PD = Optional Perforated and Dimpled

Wings

– 1R= 1.00 High 11 Ga. Offset Radial

– .75R= Optional 3/4 High 11 Ga. Offset Radial

Chain

– Hardened Roller: Flat Face 7/8 Dia. x 1/2 Wide

– Split Roller Bushing

– Links: 1/8 Thick x 11/16 High

Pan/Hinge

– Material 1/8

– Available in Any Width of 3″ Increments

– D = Optional Dimpled

– PD = Optional Perforated and Dimpled

Wings

– 1/8 Thick x 1-1/2 High – Offset Welded To Pan

Chain

– Roller: Hardened – Flat Face 1-9/16 Dia. x 1″ Wide

– Hardened Split Roller Bushing

– Links: 5/32 Thick x 1″ High

Pin

– 3/8 Dia. CR1044/1045

– Locking System – 1/8 Cotter Pin

Belt Pull – 2,500 Lbs.

Modifications

– Optional Bar Cleats, Any Size, Any Spacing.

– Optional Cover Plates, 3/8 Thick x 1-3/4″ Wide, Any Spacing

Industry News & Blog

Durable & Clean: The Power of Metal Conveyor Belts – As detailed by IQS Directory in the article “What Are the Benefits of Metal Conveyor Belts?”, the right choice in conveyor systems can significantly influence manufacturing efficiency, especially in demanding environments. Among the most resilient and high-performing solutions are metal conveyor belts, which continue to rise in popularity across industries for their unmatched strength, cleanliness,… Read More →

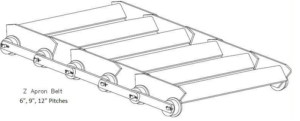

Durable & Clean: The Power of Metal Conveyor Belts – As detailed by IQS Directory in the article “What Are the Benefits of Metal Conveyor Belts?”, the right choice in conveyor systems can significantly influence manufacturing efficiency, especially in demanding environments. Among the most resilient and high-performing solutions are metal conveyor belts, which continue to rise in popularity across industries for their unmatched strength, cleanliness,… Read More → Why “Z” Apron Pan Conveyor Belts Are Essential for Heavy-Duty Industries – At May Conveyor, we take pride in designing and manufacturing conveyor belts that can withstand the most demanding industrial applications. In industries such as mining, metal processing, and foundries, conveyor belts need to handle extreme temperatures, heavy loads, and abrasive materials. Standard conveyor systems often fall short under these harsh conditions, leading to frequent breakdowns… Read More →

Why “Z” Apron Pan Conveyor Belts Are Essential for Heavy-Duty Industries – At May Conveyor, we take pride in designing and manufacturing conveyor belts that can withstand the most demanding industrial applications. In industries such as mining, metal processing, and foundries, conveyor belts need to handle extreme temperatures, heavy loads, and abrasive materials. Standard conveyor systems often fall short under these harsh conditions, leading to frequent breakdowns… Read More → Why Metal Conveyor Belts Excel in Tough Environments – As outlined by IQS Directory in the article “Metal Conveyor Belts,” metal conveyor belts provide critical performance advantages in industries where durability and strength are required. These belts are designed to handle sharp, hot, or unstable items that traditional fabric or plastic belts cannot manage. From scrap yards to forging plants, metal conveyor belts offer… Read More →

Why Metal Conveyor Belts Excel in Tough Environments – As outlined by IQS Directory in the article “Metal Conveyor Belts,” metal conveyor belts provide critical performance advantages in industries where durability and strength are required. These belts are designed to handle sharp, hot, or unstable items that traditional fabric or plastic belts cannot manage. From scrap yards to forging plants, metal conveyor belts offer… Read More → Boost Productivity with Precision Chip Conveyor Solutions – At May Conveyor, we understand that efficiency is the backbone of any successful manufacturing or metalworking operation. One of the biggest challenges in these industries is managing metal chips, shavings, and debris that accumulate during production. Without an effective solution, these byproducts can cause machine downtime, create safety hazards, and reduce overall productivity. That’s why… Read More →

Boost Productivity with Precision Chip Conveyor Solutions – At May Conveyor, we understand that efficiency is the backbone of any successful manufacturing or metalworking operation. One of the biggest challenges in these industries is managing metal chips, shavings, and debris that accumulate during production. Without an effective solution, these byproducts can cause machine downtime, create safety hazards, and reduce overall productivity. That’s why… Read More →