What are the applications for custom and specialty conveyor belts?

Specialty belts are essential when standard belts can’t meet the unique demands of specific industries, such as those requiring corrosion resistance, chemical resistance, the ability to handle high temperatures, and other challenging environmental factors. For instance, chemical resistant conveyor belts are designed to withstand harsh chemicals, while heat resistant conveyor belts can handle high-temperature environments without compromising performance.

Specialty Belt Features

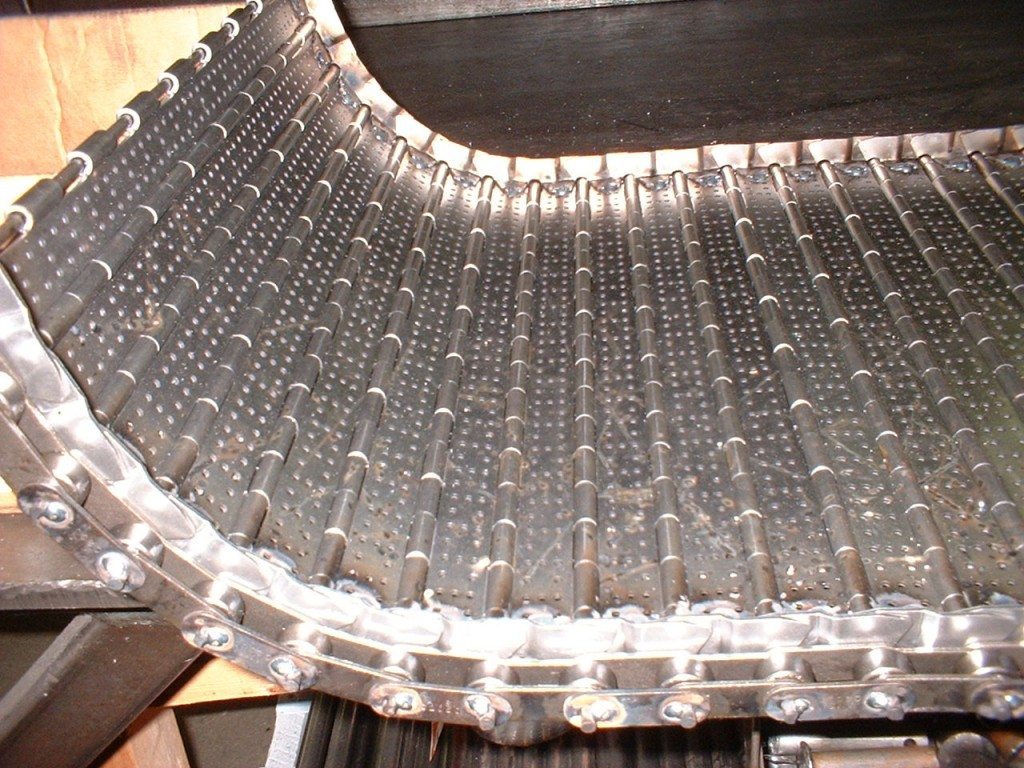

Standard belts aren’t equipped to deal with these specialized industrial factors and would have a significantly shorter lifespan. That’s why conveyor belts for waste materials handling or chain conveyor systems are often tailored to ensure maximum efficiency and durability in tough conditions. In many cases, custom belts for enhanced machining efficiency—like those made from stainless steel—are a better fit for these demanding applications, offering the strength and longevity needed to thrive in extreme environments.

Custom Belt Specifications

Pitch: 1-1/4″-12″

Length: Variable as required

Width: As Required

Material: Stainless Steel, Aluminum, Rubber, and other specialty materials.