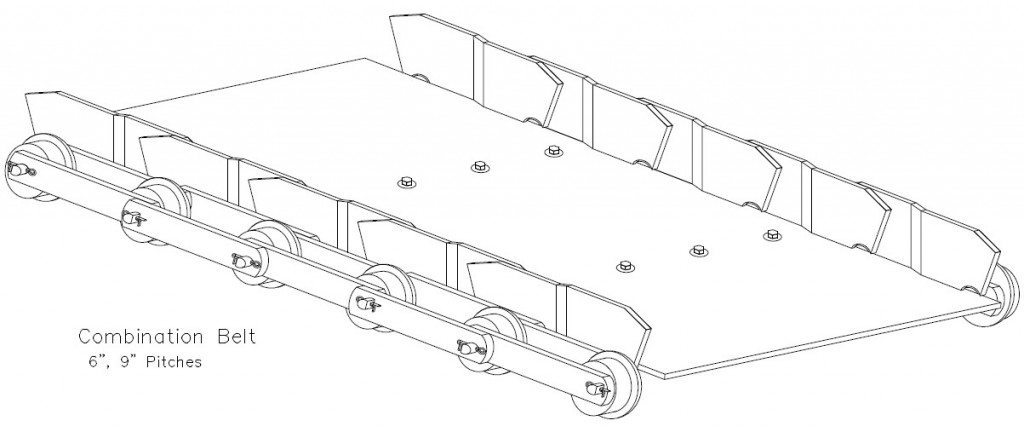

Applications

Combination belting is a lighter weight replacement for steel hinged belting. Combination conveyor belts can be used in new conveying systems or as a replacement for steel belting, with minor or no modifications. They are particularly popular in industries that require efficient waste management solutions, such as when a conveyor belt for waste management is needed to handle various types of waste materials.

You can find this type of belting being used in the following industries:

Waste & Recycling

Additionally, metal chip conveyor belts are often utilized in manufacturing settings where metal debris or chips need to be moved efficiently. For more demanding environments, heavy-duty solutions like Heavy Duty Z Apron Belts are designed to handle tougher loads and maintain durability in high-stress conditions. These types of belts are often used in systems designed for efficient waste segregation systems, where effective separation of different waste types is essential.

Specifications

Belt –

– PVC

– Rubber

Chain – Select from our 6″ Pitch Chain – Standard

Wing – 4″ High x 1/4 Interlocking Offset Welded To Chain (Other Sizes Available)

Bar Wing – 4″ Overall Height Inner Chain Bars (3″ High from Center of Roller) Width is same as Chain Bar selected. (Other Sizes Available)

C-Channel –C-4 x 5.4# x Belt Width, every other pitch

Fasteners –

3/8-16 Hex Head Bolts and Nylon Locking Insert Nuts

Oversize Fender Washers on belt surface

Optional Elevator or Button Head Bolts

Modifications –

Angle Cleats

Impact Pads

Any Size, Any Spacing

Belt –

– PVC

– Rubber

Chain – Select from our 9″ Pitch Chain – Standard

Wing – 4″ High x 1/4 Interlocking Offset Wings Welded To Chain (Other Sizes Available)

Bar Wing –

4″ Over All Height Inner Chain Bars

(3″ High from Center of Roller)

Width is same as Chain Bar selected.

(Other Sizes Available)

C-Channel –C-6 x 8.2# x Belt Width, every other pitch

Fasteners –

1/2-13 Hex Head Bolts and Nylon Locking Insert Nuts

Oversize Fender Washers on belt surface

Optional Button Head Bolts

Modifications –

Belt Support Attachments

Every Other Pitch

Angle Cleats

Impact Pads

Any Size, Any Spacing

Case Studies

May Conveyor, Inc. Rapidly Modifies a Mismatched Belt to Resume Operations

May Conveyor, Inc. Rapidly Modifies a Mismatched Belt to Resume Operations May Conveyor, Inc. Expedites Special Material Procurement to Build a Custom Apron/Beaded Pan Belt

May Conveyor, Inc. Expedites Special Material Procurement to Build a Custom Apron/Beaded Pan Belt May Conveyor, Inc. Delivers a Custom 1000′ Steel Belt in Record Time for Holiday Installation

May Conveyor, Inc. Delivers a Custom 1000′ Steel Belt in Record Time for Holiday Installation

Industry News & Blog

Seeing Opportunity Through the Conveyor Belt

Seeing Opportunity Through the Conveyor Belt Breaking Free from the Conveyor Belt Mindset

Breaking Free from the Conveyor Belt Mindset Knowing When to Step Off the Conveyor Belt

Knowing When to Step Off the Conveyor Belt