Applications

The 1.25”- 1.50″ – 2.50″ metal chip conveyor belt is designed for reliable and efficient handling of parts, stampings, die castings, screws, scrap, chips, and turnings. Whether the material is wet or dry, the conveyor performs effectively in horizontal or elevating setups, and supports both single and multiple unit systems. Ideal as a chip conveyor for CNC machines, it helps streamline operations by managing chip removal and material flow with ease.

You will find this belting being used in the following industries:

Features

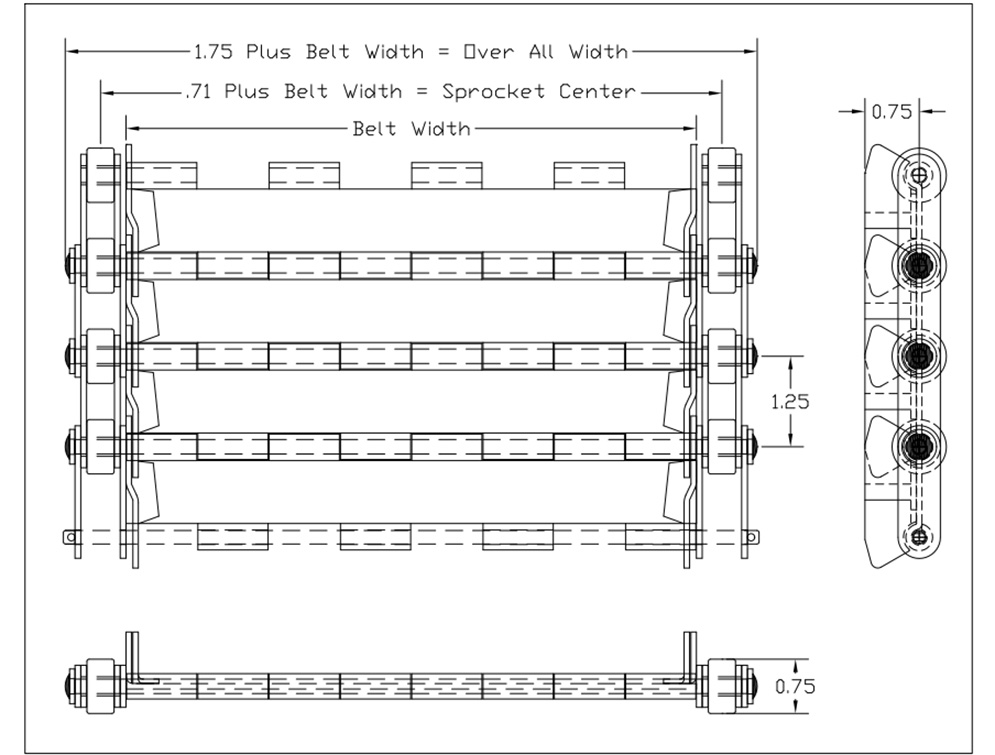

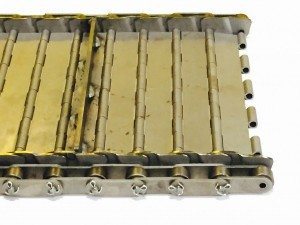

Our hinged steel belt conveyor belting is available in 1-1/4″, 1-1/2″, and 2-1/2″ pitch sizes. Designed with offset interlocking side wings that are securely welded, these belts offer exceptional durability and reliable performance. They are fully interchangeable with most major manufacturers, making them a versatile solution for a wide range of machining and metalworking applications. We also offer beaded apron belts for operations requiring added flexibility and strength. Improving CNC workflow with the right conveyor system starts with dependable belting solutions like these, streamlining chip removal and boosting efficiency.

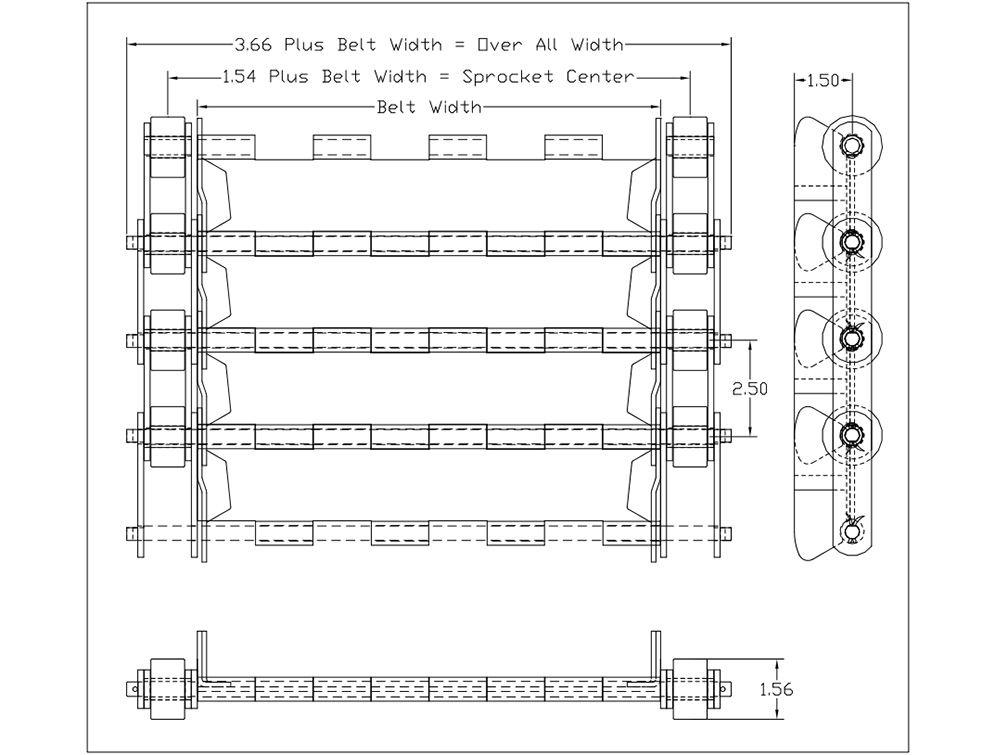

Specifications

Pan/Hinge

– Material 14 GA. (.075)

– Available in Any Width

– P = Optional Perforated

– D = Optional Dimpled

– PD = Optional Perforated and Dimpled

Wings

– .75= 3/4 High 14 Ga. Offset Welded To Pan

– .8R= Optional 13/16 High 11 Ga. Offset Radial

Chain

– Hardened Roller: Flat Face 3/4 Dia. x 3/8 Wide

– Split Roller Bushing

– Links: 3/32 Thick x 9/16 High

Pin

– 3/16 Dia. CR1044/1045

– Locking System – Welded Washer

– Belt Splice 3/32 Cotter Pin

Belt Pull – 650 Lbs.

Modifications

– Optional Bar Cleats, Any Size, Any Spacing.

– Optional Cover Plates, 3/16 Thick x 1″ Wide, Any Spacing

Pan/Hinge

– Material 14 GA. (.075)

– Available in Any Width

– P = Optional Perforated

– D = Optional Dimpled

– PD = Optional Perforated and Dimpled

Wings

– 1R= 1.00 High 11 Ga. Offset Radial

– .75R= Optional 3/4 High 11 Ga. Offset Radial

Chain

– Hardened Roller: Flat Face 7/8 Dia. x 1/2 Wide

– Split Roller Bushing

– Links: 1/8 Thick x 11/16 High

Pan/Hinge

– Material 1/8

– Available in Any Width of 3″ Increments

– D = Optional Dimpled

– PD = Optional Perforated and Dimpled

Wings

– 1/8 Thick x 1-1/2 High – Offset Welded To Pan

Chain

– Roller: Hardened – Flat Face 1-9/16 Dia. x 1″ Wide

– Hardened Split Roller Bushing

– Links: 5/32 Thick x 1″ High

Pin

– 3/8 Dia. CR1044/1045

– Locking System – 1/8 Cotter Pin

Belt Pull – 2,500 Lbs.

Modifications

– Optional Bar Cleats, Any Size, Any Spacing.

– Optional Cover Plates, 3/8 Thick x 1-3/4″ Wide, Any Spacing

Industry News & Blog

How Conveyor Systems Are Shaping Modern Material Handling – As published by Greenspace Industrial in “Revolutionizing Material Handling: The Future of Conveyor Systems at Greenspace Industrial,” modern conveyor systems are evolving to improve efficiency, flexibility, and performance in material handling operations. Innovations focus on automation, modular design, and system integration to meet changing industrial demands. Advanced conveyor solutions support streamlined workflows, reduced downtime, and… Read More →

How Conveyor Systems Are Shaping Modern Material Handling – As published by Greenspace Industrial in “Revolutionizing Material Handling: The Future of Conveyor Systems at Greenspace Industrial,” modern conveyor systems are evolving to improve efficiency, flexibility, and performance in material handling operations. Innovations focus on automation, modular design, and system integration to meet changing industrial demands. Advanced conveyor solutions support streamlined workflows, reduced downtime, and… Read More → How Conveyor Belt End-of-Life Choices Impact Sustainability – As published by ScienceDirect in “Toward the Sustainable Use of Conveyor Belts: Life Cycle Assessment of End-of-Life Options,” researchers examined how different end-of-life strategies affect the environmental impact of conveyor belts. The study evaluates options such as recycling, reuse, and disposal through a life cycle assessment framework. Findings show that selecting more sustainable end-of-life pathways… Read More →

How Conveyor Belt End-of-Life Choices Impact Sustainability – As published by ScienceDirect in “Toward the Sustainable Use of Conveyor Belts: Life Cycle Assessment of End-of-Life Options,” researchers examined how different end-of-life strategies affect the environmental impact of conveyor belts. The study evaluates options such as recycling, reuse, and disposal through a life cycle assessment framework. Findings show that selecting more sustainable end-of-life pathways… Read More → Choosing the Right Conveyor System – As presented on ResearchGate in “Study of Different Types of Conveyor System and Their Use According to the Various Needs of Different Industries,” conveyor systems are designed to move materials efficiently across manufacturing, warehousing, mining, and processing environments. Common systems include belt conveyors, roller conveyors, chain conveyors, screw conveyors, and pneumatic conveyors, each suited to… Read More →

Choosing the Right Conveyor System – As presented on ResearchGate in “Study of Different Types of Conveyor System and Their Use According to the Various Needs of Different Industries,” conveyor systems are designed to move materials efficiently across manufacturing, warehousing, mining, and processing environments. Common systems include belt conveyors, roller conveyors, chain conveyors, screw conveyors, and pneumatic conveyors, each suited to… Read More → Seeing Opportunity Through the Conveyor Belt – As described by Andy Taylor in “The Sushi Restaurant Conveyor Belt of Opportunity,” conveyor belts symbolize continuous flow and accessible opportunity. In sushi restaurants, items move predictably past customers, allowing them to engage when the timing feels right. This steady movement creates visibility, choice, and efficiency, turning motion into an interactive experience rather than a… Read More →

Seeing Opportunity Through the Conveyor Belt – As described by Andy Taylor in “The Sushi Restaurant Conveyor Belt of Opportunity,” conveyor belts symbolize continuous flow and accessible opportunity. In sushi restaurants, items move predictably past customers, allowing them to engage when the timing feels right. This steady movement creates visibility, choice, and efficiency, turning motion into an interactive experience rather than a… Read More →