Applications

Made of overlapping steel pans mounted on SBR chains, apron pan conveyor belts feature cleaner discharge and more durable service. These systems are used in tough industries and are often chosen as a mining conveyor belt or stainless steel conveyor belt due to their strength and heat resistance.

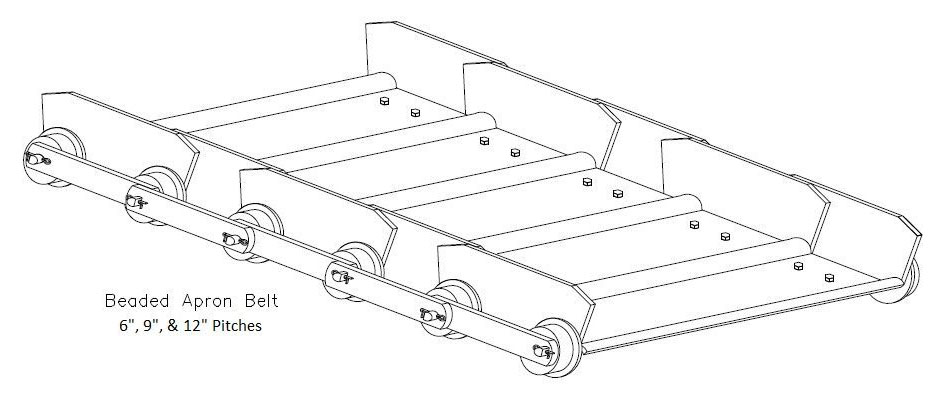

The Beaded Apron Pan Conveyor Belts are built to handle the impact of large lumps, repeated loading, and inclined conveying with minimal spillage. They also perform well in bulk material handling systems, especially where heavy loads and rough materials are involved.

Apron pan conveyors are a great fit for heavy-duty uses. They move many kinds of materials – from hot and abrasive to fine and dry. As a type of steel belt chip conveyor, they offer long-lasting performance and are often used in demanding industries.

You will mostly see this conveyor belt used in the following industries:

Specifications

Pitch – Beaded pan style conveyor belts are offered in 6″, 9″ and 12″ pitches.

Belt width range from 12″ wide to 120″ wide.

Thickness – Beaded Apron Pans thickness are available from 3/16 to 1/2.

Select a chain style from the Chain-Standard for 6″ or 9″ pitch.

Extra heavy-duty chain bars are available for 6″, 9″, and 12″ pitches.

These belts are often used as stainless steel conveyor belts in high-temperature environments and in mining conveyor belt setups where durability and low maintenance are key.

To minimize product spillage, we offer two types of systems.

1) Interlocking offset wings leak proof welded to the Beaded Apron Pan, bolted to the chain attachments.

2) Extended inner chain bars with welded attachments to bolt to the Beaded Apron Pan.

Our chains can also be configured with apron feeder chains for more rugged applications.

Pin Locking Systems: cotter pin, lock nut, lock nut with lubrication

Modifications: angle cleats, impact pads. Any size, any spacing

These systems are commonly installed where mining conveyor belt performance is required and where a stainless steel conveyor belt provides added resistance to wear and corrosion.

Case Studies

May Conveyor, Inc. Rapidly Modifies a Mismatched Belt to Resume Operations

May Conveyor, Inc. Rapidly Modifies a Mismatched Belt to Resume Operations May Conveyor, Inc. Expedites Special Material Procurement to Build a Custom Apron/Beaded Pan Belt

May Conveyor, Inc. Expedites Special Material Procurement to Build a Custom Apron/Beaded Pan Belt May Conveyor, Inc. Delivers a Custom 1000′ Steel Belt in Record Time for Holiday Installation

May Conveyor, Inc. Delivers a Custom 1000′ Steel Belt in Record Time for Holiday Installation

Industry News & Blog

Choosing the Right Conveyor System

Choosing the Right Conveyor System Seeing Opportunity Through the Conveyor Belt

Seeing Opportunity Through the Conveyor Belt Breaking Free from the Conveyor Belt Mindset

Breaking Free from the Conveyor Belt Mindset