Stamping Industry Solutions

May Conveyor provides durable, precision-engineered conveying systems specifically tailored to the needs of the Stamping industry. Their solutions—Steel Hinge Belts, Conveyor Chains, and Specialty Engineered Belting—are designed to withstand the demanding nature of metal stamping operations. Whether handling sharp scrap, metal slugs, or finished parts, May Conveyor offers proven equipment that maximizes uptime, efficiency, and longevity in both new installations and retrofit upgrades.

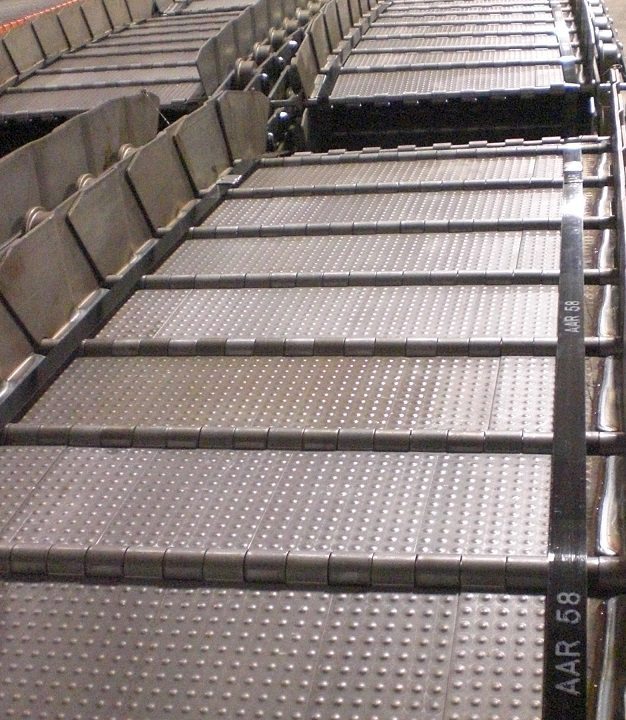

Designed for high-impact metal-handling environments, steel hinge belts excel in the rigorous demands of stamping operations.

May Conveyor’s heavy-duty chains provide essential support for conveying systems in stamping environments.

Custom-built belts handle unique requirements not met by standard designs—ideal for specialty stamping applications.

Why Choose May Conveyor for Stamping Applications

Industry-Focused Design

Equipment built for metal part handling, sharp scrap, and heavy-duty press room conditions

Customization & Compatibility

Modular options allow for tailored solutions, press integration, and easy retrofitting

Typical Applications in the Stamping Industry

| Product | Typical Use Cases | Core Benefits |

| Steel Hinge Belts | Scrap removal from presses, incline runs | Durability, impact resistance, custom cleating |

| Conveyor Chains | Belt support in high-load conveyors | Strength, reliability, oil resistance |

| Specialty Belting | Hot stamping, oil-exposed systems | Tailored materials, corrosion and heat resistance |

May Conveyor delivers rugged, efficient, and customizable conveyor systems built to meet the critical demands of the Stamping industry. Whether it’s replacing worn components or designing a new system, their belts and chains are built for precision, performance, and lasting value.