OEM Industry Solutions

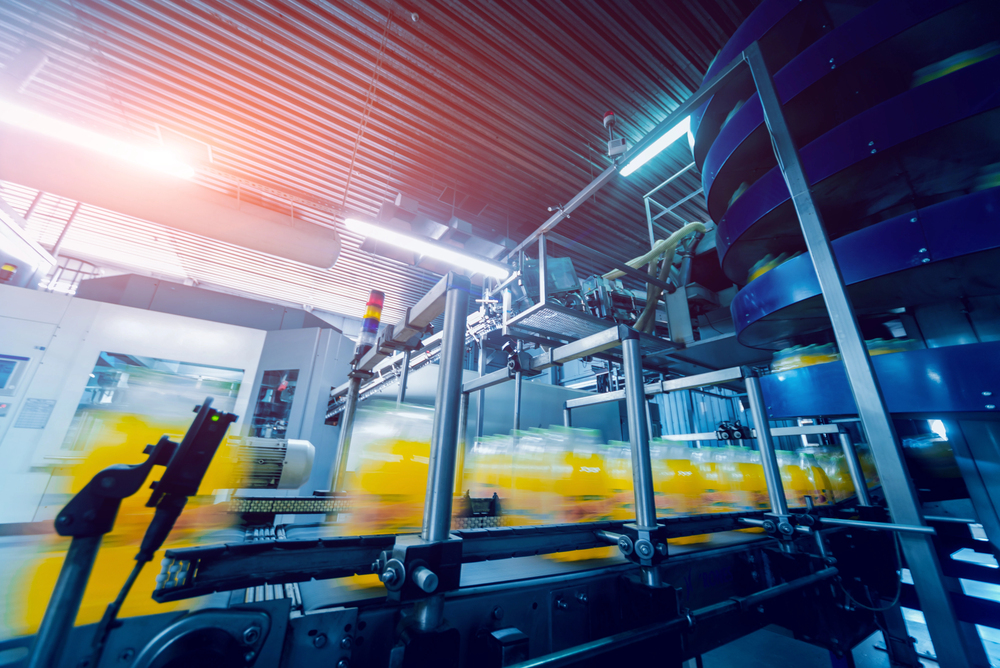

May Conveyor provides dependable, high-performance conveyor components tailored for Original Equipment Manufacturers (OEMs). With a focus on Chains, Specialty Belting, and Steel Hinge Belts, their products are designed to meet the exacting requirements of OEM environments—offering durable, customizable, and scalable solutions for integration into industrial machinery and material handling systems.

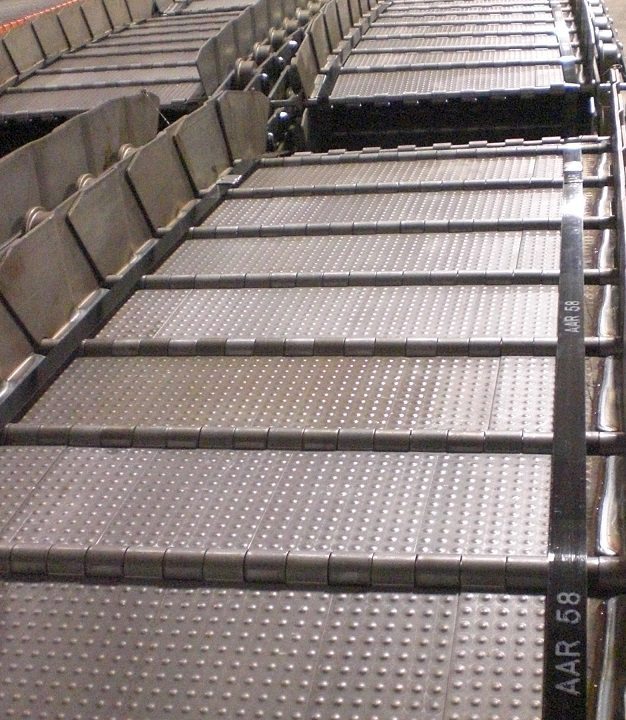

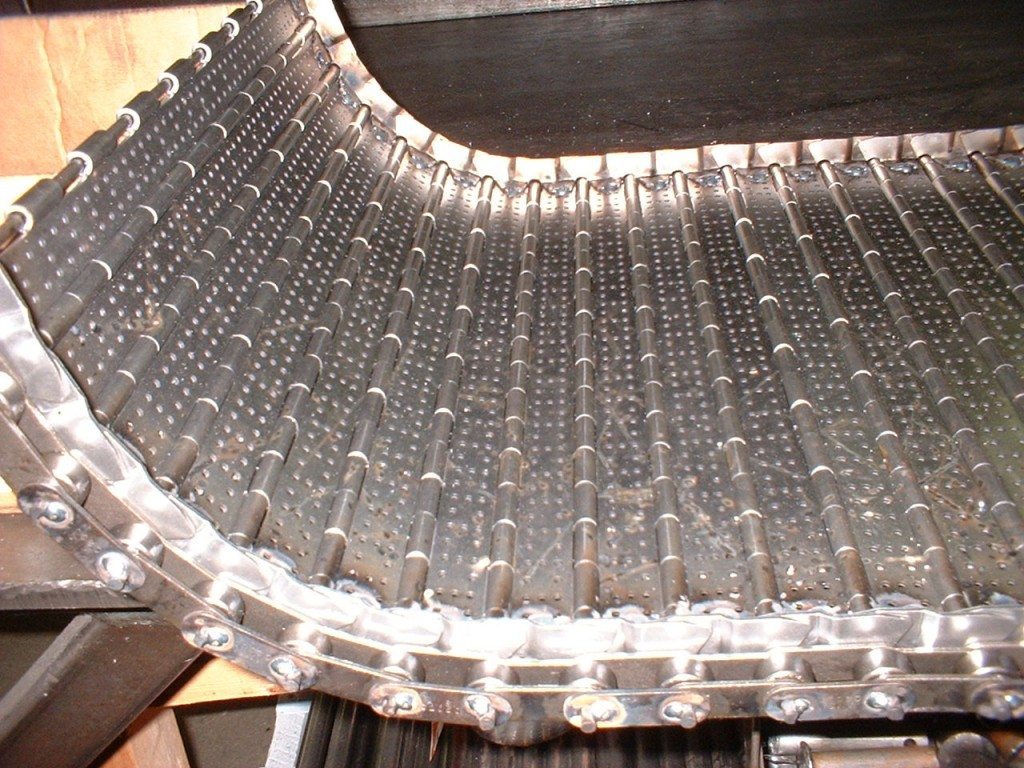

Heavy-duty steel hinge belts provide robust performance for OEM applications requiring high-strength and reliability.

Precision-engineered chains form the structural foundation for many OEM conveyor systems.

Custom-built belts designed to meet unique OEM specifications for extreme or unconventional environments.

Why Choose May Conveyor for OEM Applications

OEM-Focused Engineering

Products are designed with OEM integration in mind, offering flexibility, performance, and long service life.

Reliability

High-grade materials and manufacturing ensure consistent performance under demanding operating conditions.

Ease of Integration

Precision dimensions and customizable features streamline system design and installation.

Typical Applications in OEM

| Product | Typical Use Cases | Core Benefits |

| Steel Hinge Belts | Heavy-duty chip removal, part transfer | Rugged construction, tailored features |

| Conveyor Chains | Load-bearing support for conveyors in OEM systems | Durable, smooth-operating, precision components |

| Specialty Belting | Custom applications, harsh environments | Corrosion/heat resistance, engineered to spec |

May Conveyor delivers engineered conveyor solutions that OEMs can count on. With customizable components built to endure industrial demands and fit precise system specs, they help equipment builders achieve reliable performance and long-term efficiency.