Foundry & Mining Solutions

May Conveyor provides engineered conveyor belts for OEMs and heavy-duty systems designed for the harsh demands of the Foundry and Mining industries. Their durable product line—Steel Hinge Belts, Z-Apron Pan Belts, Beaded Apron Belts, and Conveyor Chains—is built to handle high-impact tasks, high temperatures, and rough materials. These heavy-duty conveyor systems support smooth, low-maintenance operation and help improve bulk material handling in both new builds and older systems.

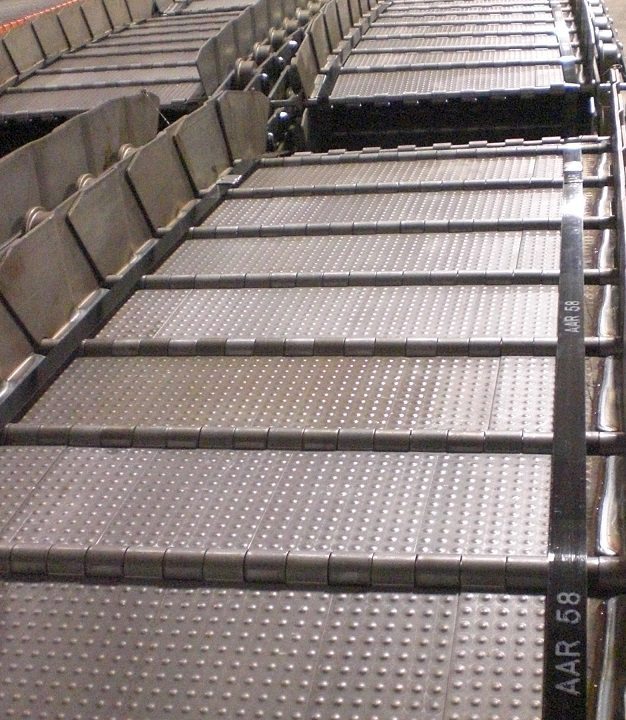

Made for the toughest work environments, May Conveyor’s Steel Hinge Belts are a core solution in foundry and mining. These belts work well with high temperature conveyor belts needs and hold up against impact and wear. They’re ideal for sites needing strong and heavy-duty conveyor systems that last.

Z-Apron Pan Belts mix strength and material control. These belts are a solid choice for managing large loads in high temperature and rough settings like foundries and mines. Their design supports heavy-duty conveyor systems, keeping uptime high and repairs low.

Built with precision, Conveyor Chains from May Conveyor form the core of many heavy-duty conveyor systems. They help move materials with ease and support high temperature conveyor belts in mining and foundry operations. These chains also fit well into systems used for metal stamping conveyor belts, giving extra value in mixed-industry use.

Why Choose May Conveyor for Foundry & Mining

Industry-Centric Engineering

Every product is built for rough foundry and mining jobs—from heat and abrasion to heavy loads. May Conveyor also offers automated conveyor solutions that boost performance while lowering manual effort.

Custom Fabrication

Custom options for width, thickness, cleats, and chain types help meet exact system needs. Whether it’s a new system or an upgrade, these engineered conveyor belts for OEMs support smooth operation.

Durability & Lifespan

Reinforced parts, tough pans, and high temperature conveyor belts extend use and cut down on maintenance. These systems are built to last under tough conditions.

Retrofit Flexibility

May Conveyor products fit into current setups, making upgrades easy without full replacements. This adds value for users who rely on heavy-duty conveyor systems daily.

Typical Applications in Foundry & Mining

| Product | Typical Use Cases | Core Benefits |

| Steel Hinge Belts | Hot scrap, metal castings, incline systems | High-impact durability, long service life |

| Z-Apron Pan Belts | Slag, foundry scrap, bulk load transfers | Strength, containment, smooth delivery |

| Beaded Apron Belts | Repetitive abrasive loads, slag transfer | High-heat resistance, secure belt tracking |

| Conveyor Chains | Belt drives in hot, abrasive environments | Low-maintenance, hardened for wear resistance |

May Conveyor delivers strong, ready-to-work automated conveyor solutions for the Foundry and Mining industries. Whether you’re updating old equipment or starting fresh with a high-output setup, May’s belts and chains provide top reliability, strength, and flexibility. They are built to meet your toughest bulk material handling needs—every step of the way.