At May Conveyor, we take pride in designing and manufacturing conveyor belts that can withstand the most demanding industrial applications. In industries such as mining, metal processing, and foundries, conveyor belts need to handle extreme temperatures, heavy loads, and abrasive materials. Standard conveyor systems often fall short under these harsh conditions, leading to frequent breakdowns and costly repairs.

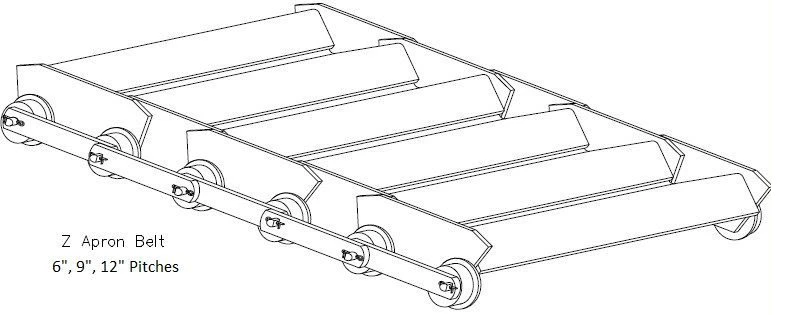

That’s where our Z” Apron Pan Belts come in. Engineered for durability and reliability, these conveyor belts are built to handle the toughest material handling challenges. In this blog, we’ll explore why apron pan conveyor belts are essential for heavy-duty industries and how they can enhance efficiency, safety, and operational longevity.

What Makes “Z” Apron Pan Conveyor Belts Unique?

Unlike traditional conveyor belts, which rely on rubber or synthetic materials, apron pan belts are constructed using interlocking metal plates. This design offers superior strength, flexibility, and resistance to impact damage. Our Z” Apron Pan Belts feature a distinctive design that allows for smooth material movement while preventing spillage, making them ideal for rugged industrial environments.

Benefits of Using “Z” Apron Pan Belts

- Exceptional Durability

Apron pan conveyor belts are built to handle extreme conditions, including high temperatures, heavy loads, and abrasive materials. Their metal construction ensures they last significantly longer than traditional rubber belts. - Reduced Downtime and Maintenance Costs

Standard conveyor belts often require frequent repairs due to tearing, stretching, or warping. Our apron pan belts are designed to withstand heavy-duty applications, reducing the need for constant maintenance and minimizing downtime. - Superior Load-Carrying Capacity

Whether you’re transporting coal, scrap metal, or other bulk materials, apron pan belts provide exceptional load-bearing strength. Their reinforced structure prevents sagging and ensures smooth material flow. - Enhanced Material Containment

One of the biggest challenges in material handling is spillage, which leads to product loss and cleanup costs. Our apron pan belts are designed with precision interlocking plates to minimize spillage and maximize efficiency. - Versatility Across Industries

“Z” Apron Pan Belts are widely used in industries such as:- Mining: For transporting ores and minerals in harsh underground conditions.

- Steel Mills: Handling hot slag, scrap, and heavy metal components.

- Foundries: Moving castings and molten materials safely.

- Recycling Plants: Processing bulk waste and scrap metal efficiently.

Custom Solutions for Your Industrial Needs

At May Conveyor, we recognize that every industry has unique material handling challenges. That’s why we offer customizable apron pan conveyor belts to meet your specific requirements. Whether you need special reinforcements, heat-resistant coatings, or a unique belt width, our team will work with you to design the perfect solution.

Invest in Reliability with May Conveyor

Choosing the right conveyor system is critical to maintaining productivity and reducing operational costs. Our Z” Apron Pan Belts offer unparalleled durability, strength, and efficiency, making them the ideal choice for heavy-duty industries.

If you’re ready to upgrade your conveyor system with a belt designed for the toughest applications, contact us today. Let May Conveyor provide you with the reliable solutions you need to keep your operations running smoothly.