The advancing technology has made transportation very easy. Now we use different types of conveyors to transport solids. Below we have made a list of some of the most common mechanical conveyors.

Belt

This is the most common type of mechanical conveyors. They are very popular in the industry for transporting material and moving parts from one place to another within the factory. They are used for almost every kind of material and they come in a variety of sizes. They are used for transporting feeding, discharging and proportioning.

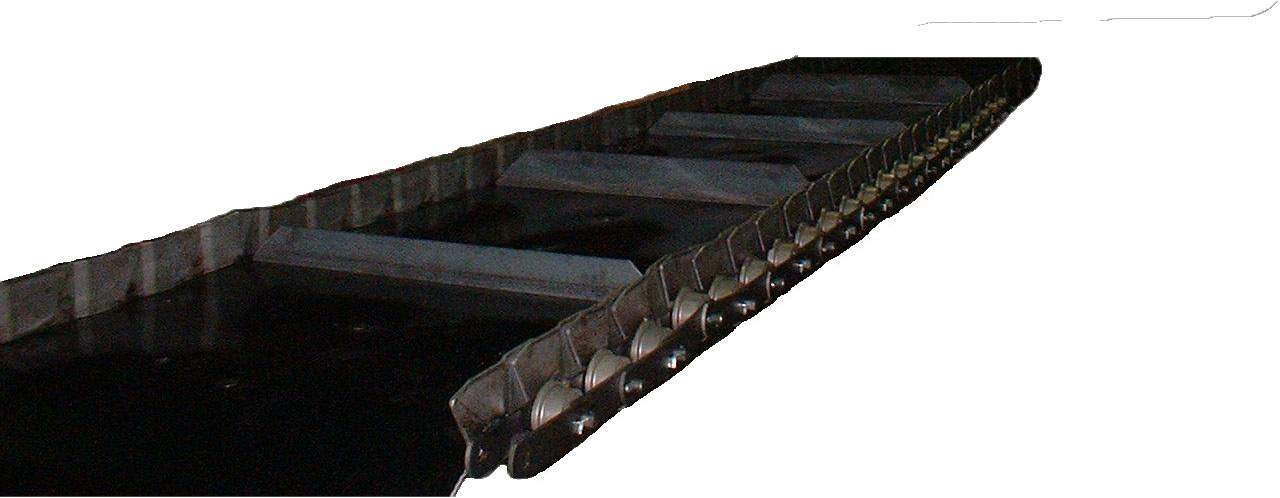

Drag Chain

Drag chains have the ability to transport solids on an incline, vertically or horizontally. In order to get the material onto the ledges, drag chains use a hopper. They are most used for transporting pieces of particle board in a wood processing facility. They can also be used for moving dry solids in both the chemical as well as the food industry. Their flexibility in loading and unloading also the ability to self-load makes them popular in the industry.

Screw

If you are looking for something really cheap and simple for moving the material, Screw is the perfect solution for you. The screw has the ability to move the material at rates almost up to 40 tons in an hour and cover a distance of 65 feet. They are used in the dairy production, food and pharmaceutical applications.

Vibratory

They have the single trough design that vibrates to move the material both upwards as well as forward. Cross-sectional areas along with the slope of the trough determine the capacity of the vibratory conveyor. Due to their flexibility and ability to handle a large number of things, they are used in a variety of industries. Some of these industries include chemical industry, food industry and many more. In the chemical industry, they are used for transporting plastic pellets, detergent powders or fertilizers.

Bucket Elevators

This is used when there is no space for horizontal conveyors. Bucket elevators consist of a number of buckets that are placed either on a single or double chain. They might be dumped at a higher level, but they are loaded at the bottom of the apparatus. One major advantage of bucket elevators is that they can operate at a speed of almost 1.5m/s which is very fast for most of the conveyors. They also have the ability to handle large capacities of material in very less time. However, buckets do not last long and lack of universal design is another disadvantage of it.