Historically, it was common for the output from longwall face equipment to greatly exceed belt conveyor system capabilities. With recent advancements in drive and control technologies and increased idler capacities, belt conveyor capabilities are now a much closer match to the output generated by high-capacity longwall equipment. Not that many years ago, underground coal mines could achieve 5000 short tph only with ideal mining and material transport conditions. Today, as the result of these advancements, it is possible for an underground coal mine running a dual longwall system to produce 10 000 short tph.

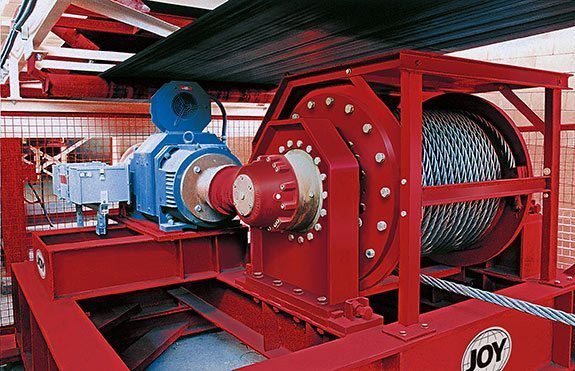

The implementation of medium-voltage controllers, improvements in controlling belt tensions and the introduction of idlers with increased carrying capacities have all contributed to the most productive underground conveyors and slope belt conveyors ever designed and installed. These advancements have dramatically improved existing conveyor power, control and reliability, as well as the carrying capacity levels required to keep up with advanced longwall equipment production. Joy Global is at the forefront of these belt conveyor advancements and has recently applied that knowledge in several key underground coal mining operations in the US.

Medium-voltage controllers

Joy Global provides custom-designed controls as part of the overall conveyor system to meet the demands of each individual installation. With controllers for head drives and tripper drives, it is now possible for conveyor systems to function effectively even in the most complex mining situations. With proven start packages, conveyor systems are now capable of extended start times in excess of 120 sec., with optimal load sharing between head drive and multiple tripper drives. All of the new conveyor installations listed in Table 1 use medium-voltage variable frequency drives (VFDs). Medium-voltage controllers are not new, but have only recently been used in high-tonnage, high-horsepower slope belt conveyor systems. The advantages includes:

Read more: Maximising Production