Hinged steel belt conveyors are used in applications that deal with metal chips, stampings, scrap metal, fasteners, forgings and castings. These conveyors allow an operation that is continuous be it in a position that is incline, decline or that is leveled. This reduces time wastage due to break downs, even during dry and wet conditions that are very demanding.

The conveyors work in many areas some of which include:

- Manufacturing

- Automotive

- Appliance

- Distribution and warehousing

- Cabinetry and furniture

- Government military and Agency

The conveyors can also b e used in the following applications:

- Oily, dirty wet parts

- CNC machines

- Scraps of steel and chips

- Press room

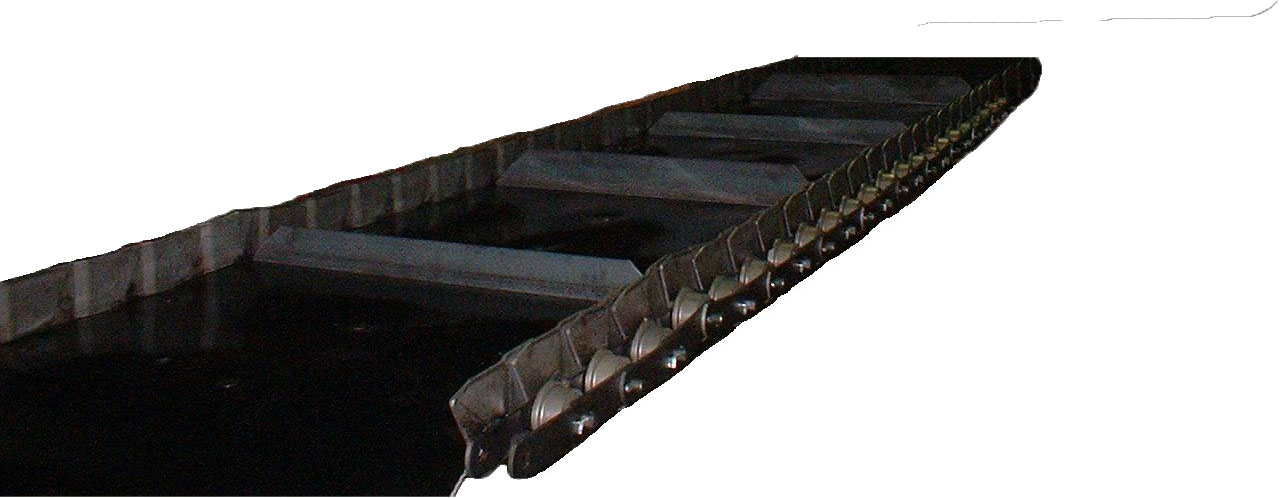

The design of the hinged steel belt conveyors are in such a way that maximum life is achieved with the least possible service done to them during their running life. They are therefore very convenient for conveying the long and bushy metal ships, swarf and turnings together with metal scraps. They are designed with flexibility in mind thus enabling them to easily fit into diverse installation layouts.

Robotic Welded Plates and a Robust Design for Long Life

In addition to the above mentioned features and design, the design of these belt conveyors employs the use of robotic plates thus giving the belt a long life. The tough applications that the conveyor is subjected to have led to the tough and robust trough and belt designs for resistance to wear tear and breakdown hence extended lifespan.

Common type of belt conveyor

The hinged steel belt conveyors are the most common among the belt conveyors in use. It can be used for transporting chips together with metal scraps. In addition to these, it can also be used in the transportation of bulky materials to the central collection points.

Advantages of the hinged steel belt conveyor

There are a number of advantages associated with this type of conveyor belts. One of this is the wide span of application. It can be used in virtually all industries and departments. The only area where its use is limited is where there are high percentages of sludge and fines in the transported materials. Under such circumstances, the use of a screw conveyor or a chain conveyor is most suitable.

At the heart of every conveyor is the belting that transports the material. May Conveyor manufactures and fabricates standard & custom conveyor belting. We are a premier manufacturer of conveyor belting of various pitch and chain configurations, for all your conveying needs. With decades of experience, we have developed a quality product featuring a fully closed and totally concentric hinge loop. These features provide for stronger and better wearing hinge assembly, resulting in longer belt life with less maintenance.

Belting is what sets us apart from others as we make our dies in-house by the May Tool & Die Group. These precision components meet all automotive standards helping us become known as a quality supplier in the marketplace today. Contact us today!