The choice of a conveyor belt repair options will highly depend on the extensiveness of repair, the section of fault and the resources available. There are three major conveyor belt repair options as discussed below.

Vulcanized Repairs

These are the conveyor belt repair that are closest to match the original manufacturing procedures that the belt was subjected to in the factory. By the use of vulcanization process, the missing or damaged sections of the carcass and the cover are replaced with minimal sacrifice of the strength of the conveyor belt. It is the most comprehensive among the three major conveyor belt repair options. The main aim of the vulcanization process is to restore or repair the damaged cover as well as the carcass areas in a carefully rematch, cleaned and trimmed fashion. After the cleaning and the cementing, a new uncured rubber cover is then inserted. Heat and pressers are then used in curing the repair thus producing a nearly imperceptible result after the conveyor has been returned back to service.

Metal Fastener Repairs

This is an entirely different procedure and principle as far as handling a damaged conveyor belt is concerned. Metal fasteners are in most cases the only spicing method that is employed in most belt applications. This therefore establishes their suitability when it comes to belt repairs. Metal fasteners that are strictly used for splicing will always have a number of attachment formats. These include bolts, hooks, and rivets together with staples. For a number of bulky materials handling belts, the most selected fastener in this conveyor belt repair option is the bolted plate type.

The bolt type fasteners have the advantage of being fundamentally simply to use or rather to apply. They are also durable and good at gripping and their installation is normally relatively fast. For cover only maintenance and repairs, the metal fasteners won’t be applicable.

Cold Cure Repairs

These are similar to the previously discussed hot vulcanization repairs. This is in the sense that the cover, carcass or belt components damaged are restorable via the insertion of new materials. However, rather than heat and pressure being used in curing, chemical cure is used to achieve the adhesion to the conveyor virgin belt.

Cold cure materials include cover repair strips as well as patches, cements, fabric ply materials together with various urethane filters and putties. You need good workmanship so as to achieve successful cold cure repairs. There is need for cleanliness, dryness as well as patience for some considerable time for the chemical action to cure the materials.

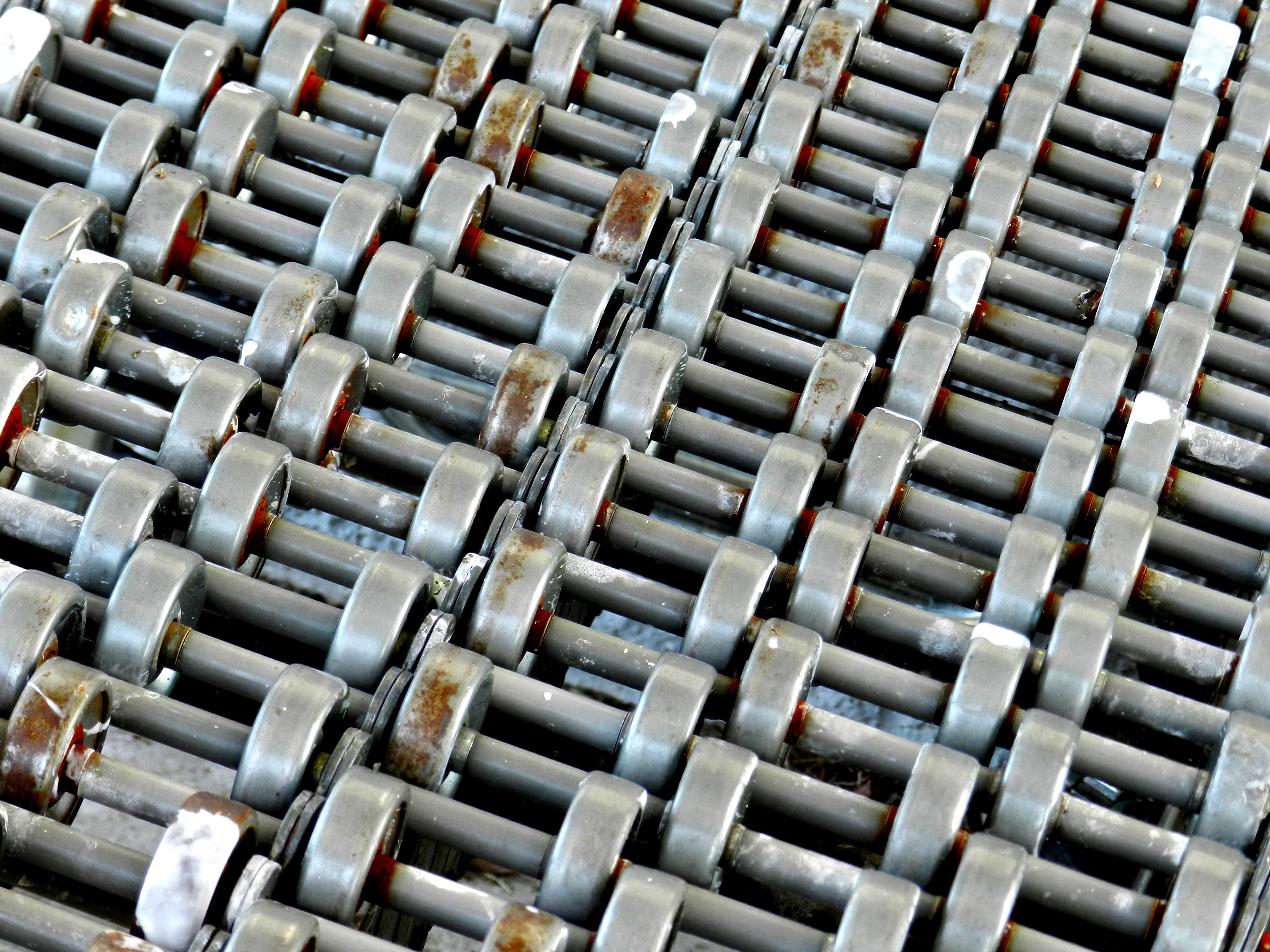

At the heart of every conveyor is the belting that transports the material. May Conveyor manufactures and fabricates standard & custom conveyor belting.

We are a premier manufacturer of conveyor belting of various pitch and chain configurations, for all your conveying needs. With decades of experience, we have developed a quality product featuring a fully closed and totally concentric hinge loop. These features provide for stronger and better wearing hinge assembly, resulting in longer belt life with less maintenance. Contact us today!